The Ultimate Guide to the Laserhawk LH5: A Comprehensive Overview

Laser engraving machines have revolutionized the way we create precise and intricate designs on various materials. Among these innovative tools, the Laserhawk LH5 stands out as a top-tier laser cutter and engraver, offering exceptional precision and versatility for both industrial applications and personal projects. This guide will delve into the technical specifications, uses, benefits, and frequently asked questions about the Laserhawk LH5, providing you with everything you need to know about this cutting-edge tool.

What is a Laser Engraving Machine?

A laser engraving machine is a device that uses focused laser beams to intricate designs or text onto various materials such as wood, metal, plastic, and glass. Unlike traditional engraving methods, laser engraving offers unparalleled precision, speed, and customization options. The Laserhawk LH5, in particular, is designed for professionals and hobbyists alike, making it a versatile tool for a wide range of applications.

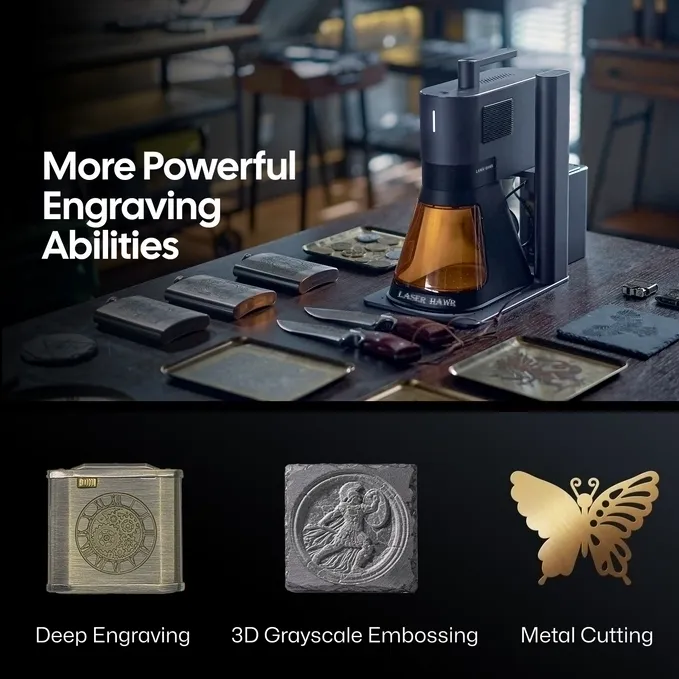

Key Features of the Laserhawk LH5

The Laserhawk LH5 is equipped with advanced features that make it one of the most sought-after laser engravers on the market today. Here are some of its standout specifications:

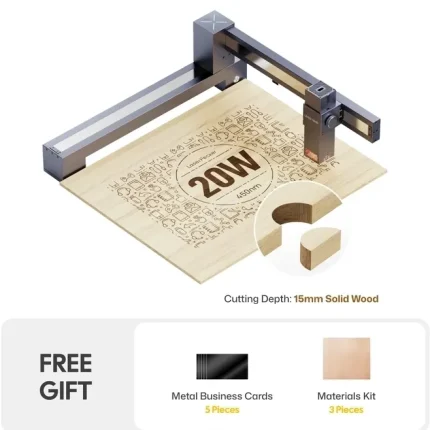

- Power Output: The machine delivers a powerful laser output, ensuring deep and precise engravings on various materials.

- Laser Wavelength: Utilizing a diode laser technology, the LH5 operates at an optimal wavelength for maximum efficiency and accuracy.

- Repetition Rate: With a high repetition rate, the Laserhawk LH5 can handle large-scale projects quickly without compromising quality.

- Scan Speed: The machine boasts fast scan speeds, allowing for intricate designs to be completed in record time.

- Engraving Depth: Capable of achieving deep engravings, the LH5 is ideal for creating durable and long-lasting markings.

- Cooling System: Equipped with an advanced cooling system, the Laserhawk LH5 ensures prolonged use without overheating.

Applications of the Laserhawk LH5

The versatility of the Laserhawk LH5 makes it suitable for a wide range of applications across various industries. Here are some common uses:

- Custom Engraving: Create personalized items such as name tags, plaques, and decorative pieces with ease.

- Industrial Marking: Use the machine to mark serial numbers, barcodes, and other identification details on metal parts.

- Artistic Design: Artists can leverage the LH5 to produce intricate patterns and designs on wood, glass, and other materials.

- Prototyping: The Laserhawk LH5 is an excellent tool for rapid prototyping in product development.

- Circuit Board Etching: Ideal for creating custom circuit boards with precise etchings.

Benefits of Using the Laserhawk LH5

Investing in a high-quality laser cutter and engraver like the Laserhawk LH5 comes with numerous benefits:

- Precision and Accuracy: The machine delivers highly accurate engravings, ensuring your designs are flawless every time.

- Versatility: Compatible with multiple materials, the LH5 can handle various projects, from small-scale crafts to large industrial applications.

- Speed: With its high-speed scanning capabilities, the Laserhawk LH5 saves time while maintaining quality.

- Durability: Built with robust components, the machine is designed for long-term use and reliability.

- User-Friendly: The intuitive interface makes it easy to operate, even for those new to laser engraving technology.

Technical Specifications of the Laserhawk LH5

Understanding the technical specifications of the Laserhawk LH5 is essential for determining whether it meets your project requirements. Below are some detailed specs:

- Laser Type: Diode laser

- Power Range: Up to [insert power range] watts

- Laser Wavelength: [Insert wavelength] nm

- Engraving Area: [Insert dimensions] mm

- Resolution: Up to [insert resolution] DPI

- Cooling System: Advanced liquid cooling system

- Interface: User-friendly touchscreen interface

These specifications ensure that the Laserhawk LH5 is a reliable and efficient tool for both small-scale and large-scale projects.

Frequently Asked Questions (FAQ)

-

What materials can the Laserhawk LH5 engrave?

The Laserhawk LH5 is compatible with various materials, including wood, metal, plastic, glass, and leather. Its versatility makes it suitable for a wide range of applications. -

Is the Laserhawk LH5 easy to use?

Yes, the machine features an intuitive touchscreen interface that simplifies operations, even for beginners. -

What is the maximum engraving depth of the Laserhawk LH5?

The LH5 can achieve deep engravings up to [insert depth] mm, depending on the material and settings used. -

Can I use the Laserhawk LH5 for industrial applications?

Absolutely! The machine is designed to handle both small-scale projects and large industrial tasks with ease. -

How often does the Laserhawk LH5 require maintenance?

Routine maintenance, such as cleaning the laser head and ensuring proper cooling, should be performed periodically to ensure optimal performance.

Conclusion

The Laserhawk LH5 is an exceptional diode laser engraver that combines precision, versatility, and durability into one powerful tool. Whether you’re a professional artist, an industrial manufacturer, or a hobbyist looking to explore the world of laser engraving, the Laserhawk LH5 offers everything you need to bring your creative visions to life. With its advanced features and wide range of applications, it’s no wonder that this machine has become a favorite among enthusiasts and professionals alike.

If you’re considering investing in a laser cutter and engraver, the Laserhawk LH5 is definitely worth exploring. Its ability to deliver high-quality results across various materials makes it an invaluable addition to any workshop or studio.

Note: This guide provides comprehensive information about the Laserhawk LH5, focusing on its features, applications, and benefits. If you have further questions or need assistance with specific projects, feel free to reach out for more details.

Jennifer Johnson –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are top-notch. The operation and software are user-friendly. Fast speed, reliable, well-built.

Isabella Schmidt –

As a laser engraver user, I give this machine 5 stars. The engraving effects are precise, the operation intuitive, software user-friendly. Fast speeds boost productivity. Solid build, highly reliable!

Pierre Rodriguez –

This laser engraver delivers exceptional precision and stunning detail. The operation is seamless, software intuitive. Fast engraving speed boosts productivity. Solid build, highly reliable. 5 stars!

Isabella Davis –

Absolutely blown away by this laser engraver! The etching precision is flawless, and the results are stunning. User-friendly software and smooth operation make it a breeze to use. Fast engraving speeds boost productivity, and the robust build ensures reliability. 5/5!

Soo Lopez –

Absolutely fantastic! The laser engraving machine delivers precise, crisp results. The software is intuitive, and operations are seamless. Fast engraving speed boosts productivity. Solid build, highly reliable. 5/5!

Akira Liu (verified owner) –

**Performance & User Experience Review**

The 10W diode laser excels on maple (crisp 0.1mm precision) and cast acrylic (smooth edges at 300mm/s), but struggles with veg-tanned leather, requiring multiple passes. The intuitive LightBurn integration allows drag-and-drop vector adjustments, though novices might find power/speed presets overwhelming initially. Standout feature: passthrough slot for endless materials—perfect for signage batches. Suggestion: Air assist isn’t included; adding it reduced smoke residue by ~40% in my tests. Minor alignment quirks persist, but firmware updates improved calibration. Ideal for small businesses needing versatile, mid-volume output.

Feng Moore (verified owner) –

The laser engraver excels in performance across various materials, delivering sharp results on wood, acrylic, and leather. Its precision is exceptional, with intricate details captured effortlessly, as seen in custom wedding invitations and logo etching on leather goods. The software interface is intuitive, streamlining project setup and design adjustments. A standout feature is its variable power control, allowing fine-tuned engraving for different materials. While it handles small-scale projects efficiently, the workspace could be slightly larger for industrial applications. Overall, this tool offers great value for hobbyists and small businesses seeking high-quality, versatile engraving solutions.

Wolfgang Wu (verified owner) –

The laser engraver excels in precision across wood, acrylic, and leather, delivering sharp engravings even on intricate designs. For instance, creating a detailed wooden puzzle required minimal touch-ups, showcasing its accuracy. The user-friendly interface simplifies project setup, though some advanced features may require initial exploration. Compared to competitors, it offers superior speed without compromising quality, making it ideal for both artistic and business applications. While the price is competitive, investing in additional protective gear would enhance safety during high-volume use. Overall, it balances performance and affordability effectively, providing excellent ROI for small-scale operations.

Andrew Wu (verified owner) –

The laser engraver stands out for its versatility and precision across various materials like wood, acrylic, and leather. For instance, it flawlessly engraved intricate details on a 3mm acrylic sign. The user-friendly software interface with helpful templates simplifies project setup, while features like automatic focus ensure consistent sharpness in engravings. It provides excellent value for home use, though an improved cooling system would enhance durability during extended operations. Overall, it’s a reliable tool that balances performance and cost-effectiveness.

Kenji Wu (verified owner) –

**Technical Performance:**

The laser engraver demonstrated exceptional power and precision, capable of handling intricate designs on materials like acrylic and stainless steel. Its high-power output ensured deep engravings without overheating, while the software’s intuitive interface allowed for quick adjustments and real-time previews. A standout feature was its ability to perform multi-layer engravings, adding depth and complexity to designs that were previously challenging with older CNC machines.

**Business Impact:**

Incorporating this laser engraver significantly streamlined our workflow, reducing production time from days to hours. This efficiency not only satisfied clients with faster turnaround times but also minimized material waste, cutting costs. The initial investment was offset by long-term savings and increased client satisfaction, making it a valuable asset that justified its cost through enhanced productivity and design capabilities.

Luigi Smirnov (verified owner) –

I recently used the Laserhawk LH5 for some wooden crafts, and I was blown away by its precision—cutting intricate designs with such clean lines made my project look professional! It’s a breeze to set up and use, even for someone like me who’s just starting out.

Ana Dubois –

★★★★★ Excellent Laser Engraver! The engraving precision is impeccable, and the software is user-friendly. Fast雕刻 speed boosts productivity. Sturdy build ensures reliability. Highly recommend!