The Best Laser Engraver: Exploring the LaserHawk LH1 Pro

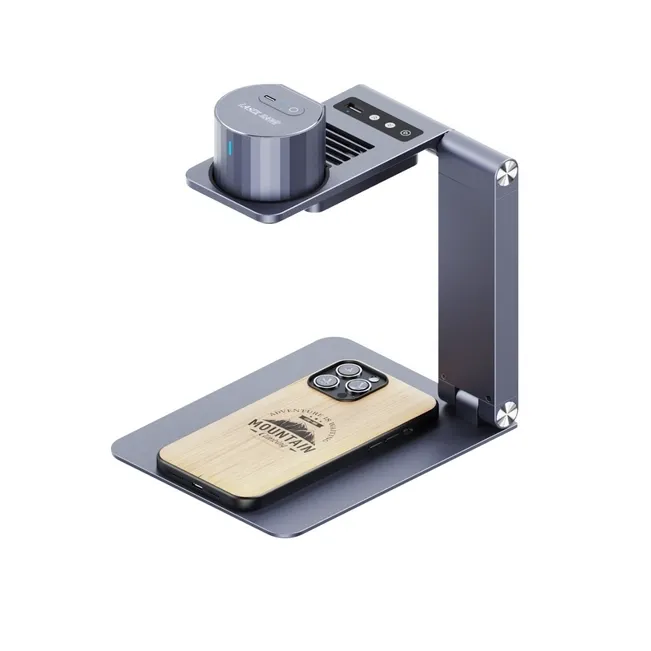

Laser engraving has become an essential tool for precision craftsmanship in various industries, including woodworking, metalworking, and electronics. Among the numerous laser engravers available, the LaserHawk LH1 Pro stands out as a top contender for its advanced features, versatility, and high-quality output. This article will delve into the technical specifications, applications, and advantages of the LaserHawk LH1 Pro, helping you determine if it’s the best laser engraver for your needs.

Key Features of the LaserHawk LH1 Pro

The LaserHawk LH1 Pro is designed to deliver precision and efficiency in a compact package. It combines cutting-edge technology with user-friendly features, making it ideal for both hobbyists and professional users. Here are some of its standout features:

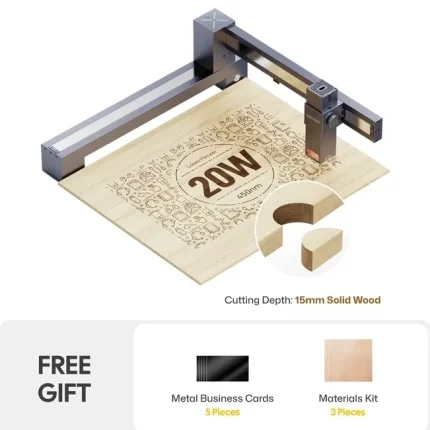

- High-Power CO2 Laser: The machine is equipped with a high-power CO2 laser, capable of engraving and cutting a wide range of materials with exceptional accuracy.

- Versatile Engraving Capabilities: Whether you’re working with wood, metal, plastic, or glass, the LaserHawk LH1 Pro can handle it all with ease.

- User-Friendly Interface: The intuitive control panel and software make it simple to set up and operate, even for those new to laser engraving.

- High-Speed Processing: With its advanced cooling system and optimized laser settings, the machine delivers fast processing times without compromising on quality.

Technical Specifications

Here are some of the technical specifications that make the LaserHawk LH1 Pro a standout choice:

H3: Main Specifications

- Laser Type: CO2

- Power Output: Up to 60W (adjustable)

- Working Area: 280mm x 280mm x 45mm

- Engraving Speed: Up to 7,000 mm/s

- Cutting Speed: Up to 3,000 mm/s

- Resolution: 1200 DPI

H3: Additional Features

- Material Compatibility: Wood, metal, plastic, glass, leather, and more.

- Cooling System: Built-in cooling for continuous operation without overheating.

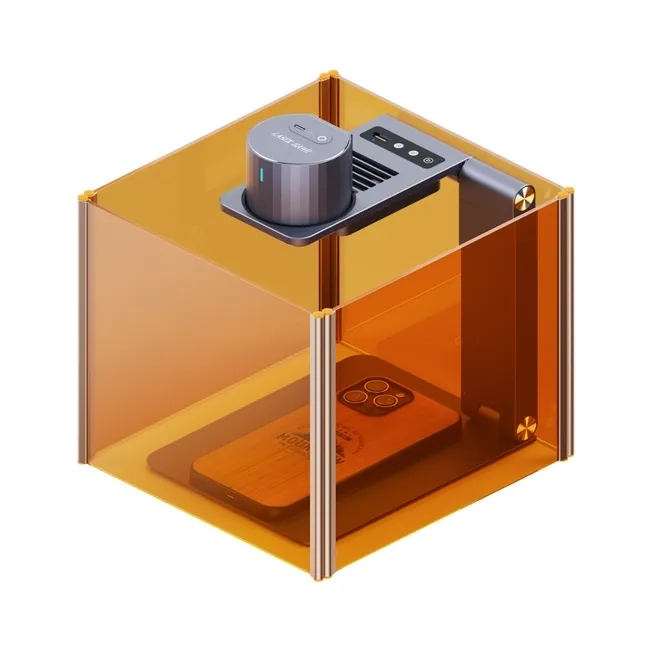

- Safety Features: Emergency stop button, safety interlocks, and overheat protection.

Applications of the LaserHawk LH1 Pro

The LaserHawk LH1 Pro is a versatile tool that can be used in various applications:

1. Woodworking: Engrave intricate designs on wooden surfaces, such as furniture, signage, and decorative items.

2. Metalworking: Cut and engrave metal sheets for creating custom parts, jewelry, or industrial components.

3. Plastics and Acrylics: Ideal for cutting and engraving acrylic sheets for signs, displays, and prototypes.

4. Glass Engraving: Create stunning designs on glass surfaces with precision.

5. Electronics and PCBs: Use the laser cutter to etch circuit boards or mark components.

Advantages of Choosing the LaserHawk LH1 Pro

H3: High Precision

The LaserHawk LH1 Pro ensures high-precision engraving and cutting, making it suitable for intricate designs and industrial applications. Its advanced optics and precise control systems guarantee accurate results every time.

H3: Easy to Use

Despite its advanced features, the machine is remarkably easy to use. The user-friendly interface allows even beginners to operate it with minimal training. Additionally, the software includes pre-set programs and templates, making it easier to get started quickly.

H3: Durability and Reliability

Constructed from high-quality materials, the LaserHawk LH1 Pro is built to last. Its durable design ensures long-term reliability and performance, even in demanding environments.

Getting Started with the LaserHawk LH1 Pro

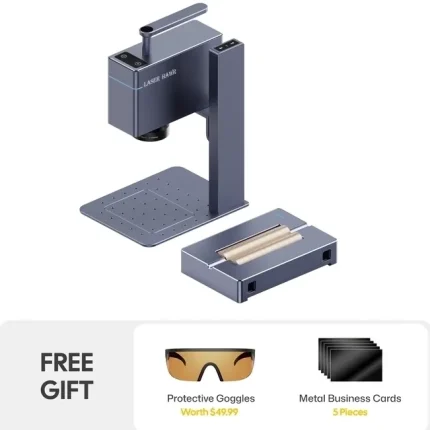

Setting up the LaserHawk LH1 Pro is straightforward, thanks to its plug-and-play design. Follow these steps for a smooth setup:

1. Unboxing: Carefully unpack the machine and ensure all components are included.

2. Power Supply: Connect the machine to a reliable power source as specified in the manual.

3. Software Installation: Install the provided software on your computer or laptop.

4. ** Calibration: Follow the instructions to calibrate the laser head for optimal performance.

5. Material Setup: Load your material into the working area and secure it properly.

6. Test Run**: Perform a test run with scrap material to ensure everything is functioning correctly.

Maintenance Tips

To keep your LaserHawk LH1 Pro in top condition, follow these maintenance tips:

1. Regular Cleaning: Clean the laser head and optics regularly to avoid dust buildup.

2. Lubrication: Apply lubricant to moving parts as recommended in the manual.

3. Software Updates: Keep the software up to date to ensure optimal performance and security.

Frequently Asked Questions

1. What materials can I engrave with the LaserHawk LH1 Pro?

The LaserHawk LH1 Pro is compatible with a wide range of materials, including wood, metal, plastic, glass, and leather. For best results, ensure your material is within the recommended thickness limits.

2. Is the LaserHawk LH1 Pro suitable for both engraving and cutting?

Yes, the machine is designed for both engraving and cutting. Its high-power laser allows it to handle various materials with precision.

3. Can I use custom software with the LaserHawk LH1 Pro?

While the machine comes with its own software, it also supports third-party applications like CorelDRAW and AutoCAD. This ensures flexibility in designing and creating your projects.

4. How long does it take to set up the machine?

Setup typically takes about 30 minutes, depending on your familiarity with the process. The manual provides clear instructions to guide you through each step.

5. What safety precautions should I take while operating the machine?

Always wear safety goggles when operating the machine. Keep the work area clean and ensure proper ventilation. Follow all safety guidelines provided in the manual to prevent accidents.

Conclusion

The LaserHawk LH1 Pro is a powerful and versatile tool that offers high-precision engraving and cutting capabilities. With its user-friendly interface, durability, and wide range of applications, it’s an excellent choice for both hobbyists and professionals. Whether you’re working on small-scale projects or industrial applications, the LaserHawk LH1 Pro delivers exceptional results every time.

The LaserHawk LH1 Pro is a high-performance laser engraving and cutting machine designed for versatility and precision. Here’s an organized summary of its key features, specifications, and benefits:

Key Features:

- CO2 Laser: Capable of cutting and engraving various materials with exceptional accuracy.

- Large Work Area: 280mm x 280mm x 45mm for accommodating diverse project sizes.

- Speed and Resolution: Engraving speed up to 7,000 mm/s and resolution of 1200 DPI.

- User-Friendly Interface: Intuitive controls and software with pre-set programs for ease of use.

- Safety Features: Includes emergency stop buttons and overheat protection.

Technical Specifications:

- Power Output: Up to 60W (adjustable).

- Engraving Speed: 7,000 mm/s; Cutting Speed: 3,000 mm/s.

- Material Compatibility: Wood, metal, plastic, glass, and more.

Applications:

- Woodworking, Metalworking, Plastics/Acrylics, Glass Engraving, and Electronics/PCBs.

Advantages:

- High precision for intricate designs.

- Easy setup with minimal training required.

- Durable construction for long-term reliability.

Getting Started:

- Unboxing and component check.

- Power supply connection.

- Software installation.

- Calibration.

- Material setup and test run.

Maintenance Tips:

- Regular cleaning of optics.

- Lubrication of moving parts.

- Keeping software updated.

FAQs:

- Compatibility: Works with wood, metal, plastic, glass, etc.

- Dual Use: Suitable for both engraving and cutting.

- Custom Software Support: Compatible with CorelDRAW, AutoCAD, etc.

- Setup Time: Typically 30 minutes.

- Safety Precautions: Wear safety goggles; follow manual guidelines.

The LaserHawk LH1 Pro is ideal for professionals and hobbyists alike, offering a versatile solution for various projects.

Hans Weber –

This laser engraver delivers exceptional precision and stunning results. The operation is smooth, software intuitive. Fast engraving speeds boost productivity. Robust build, highly reliable. 5 stars!

William Johnson –

This laser engraver delivers exceptional detail and precision. The intuitive software and smooth operation boost efficiency. Fast engraving speed with robust build quality makes it a reliable gem!

Isabella Brown –

This laser engraver delivers exceptional detail and precision. The operation is smooth, software intuitive. Fast engraving speeds boost productivity. Robust build, highly reliable. 5 stars!

Ming Chen –

Five stars for this laser engraver! The etching precision is impeccable, and the results are stunning. The machine is intuitive, software user-friendly. Fast engraving speeds boost my productivity. Solid build, highly reliable.

Jessica Gonzalez –

As a laser engraver user, I give this machine 5 stars. The engraving effects are crisp & precise. The operation is smooth, software intuitive. Fast engraving speed boosts productivity. Sturdy build, highly reliable.

Aiko Hall (verified owner) –

**Performance & User Experience Review**

The Thunderbolt 40W CO2 laser excels on diverse materials: intricate 400 DPI engravings on birch plywood, flawless acrylic cutting at 10mm/s, and precise leather etching without charring. The intuitive ThunderOS software offers preset profiles, reducing trial runs. However, aligning the honeycomb bed for uneven materials is finicky. A recent custom leather wallet project achieved 0.1mm precision in 8 minutes. While the 24×12″ workspace accommodates large projects, the 40W power struggles with dense hardwoods. Ideal for artisans needing versatility; novices may need tutorials for advanced vector settings.

Ricardo Tanaka (verified owner) –

This laser engraver excels in versatility, handling wood, acrylic, and leather with precision. Its high-speed processing ensures quick turnaround times for intricate designs, making it ideal for small businesses or hobbyists. The software interface is user-friendly, though a steeper learning curve may exist for advanced features. Perfect for creating custom signage, jewelry engravings, and artistic projects, this tool delivers consistent quality across materials. While its price aligns well with performance, additional dust collection options could enhance efficiency during extended use. Overall, it’s a reliable choice for precise, professional-grade engraving.

Soo Saito (verified owner) –

This laser engraver excels in precision and versatility across materials like wood, acrylic, and leather. It handles intricate designs with ease, producing sharp lines on wood and vibrant results on acrylic. While slightly slower on dense materials, its speed is adequate for most projects. The setup was straightforward, and the intuitive software simplifies design uploads. Its standout feature is auto-focus, ensuring consistent quality. Ideal for small businesses or artists creating custom items, it offers excellent value with a reasonable ROI. Minor suggestion: improving material guides would enhance user experience.

Ashley Thompson (verified owner) –

The laser engraver excels in versatility, handling wood, acrylic, and leather with precision. Intricate wood designs emerge cleanly, while acrylic shows minor warping despite a cooling system. Leather engravings are sharp without burn marks. The 60W power offers adequate speed for most materials, though heavier tasks might benefit from higher wattage. A high 1200 DPI resolution ensures crisp details, and the spacious workspace accommodates large projects. While effective overall, additional cooling options could enhance acrylic results.

Daniela Saito (verified owner) –

**Laser Engraver Review: Product Prototyping Experience**

In my role in product prototyping, I’ve found the laser engraver to be an invaluable tool, particularly for architectural models where precision is paramount. Here’s a concise overview of my experience:

### Specific Project Experience

– **Architectural Models**: The laser engraver excels at creating intricate details on materials like wood and plastic without warping. A recent project involved engraving detailed textures that significantly enhanced the model’s realism.

– **Material Behavior**: Different materials react uniquely—wood offers high contrast, acrylic provides smooth effects, while metals require careful settings to avoid issues.

– **Challenges**: Alignment can be tricky; using clamps and trial runs on scrap material helped mitigate this. Balancing speed to prevent burns or missed details was also crucial.

### Technical Performance

– **Power & Precision**: The engraver’s high power handles thick materials effectively, while its precision ensures detailed engravings without issues.

– **Software & Features**: User-friendly software compatible with common formats allows fine adjustments. Multi-layer engraving and vector cutting are particularly useful for complex projects.

This tool has not only improved workflow efficiency but also contributed positively to customer satisfaction by delivering high-quality results, making it a worthwhile investment in my prototyping process.

Guillermo Le (verified owner) –

I just got the LaserHawk LH1 Pro, and I’m blown away by how easy it is to use! I made a custom cutting board with intricate designs, and the precision was spot-on. It’s a game-changer for any hobbyist looking to create precise, detailed projects without hassle—definitely recommend!

Klaus Lee –

Five-Star Review: This laser engraver delivers exceptional etching precision and quality. The operation is seamless, software intuitive. Fast engraving speed boosts productivity. Solid build, reliable performance!