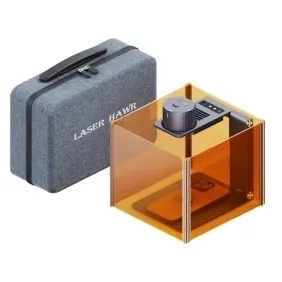

The Best Laser Engraver: Exploring the LaserHawk LH1 Pro

Laser engraving has become a cornerstone of modern manufacturing, craftsmanship, and artistic expression. Among the numerous laser engraving machines available in the market, the LaserHawk LH1 Pro stands out as one of the most versatile and high-performance tools for precision cutting and engraving. Designed to meet the demands of professionals and hobbyists alike, this machine combines advanced features with user-friendly operation, making it a top contender for those seeking the best laser engraver in their toolkit.

In this comprehensive guide, we will delve into the technical specifications, applications, advantages, and considerations when using the LaserHawk LH1 Pro. Whether you’re an artist, a jeweler, or a small-scale manufacturer, understanding the capabilities of this machine can help you decide if it’s the right tool for your projects.

Technical Specifications of the LaserHawk LH1 Pro

Before diving into its applications and benefits, let’s take a closer look at the technical specifications that make the LaserHawk LH1 Pro a standout laser engraver:

- Power Output: The machine offers a powerful 40W CO2 laser, capable of handling a wide range of materials with precision.

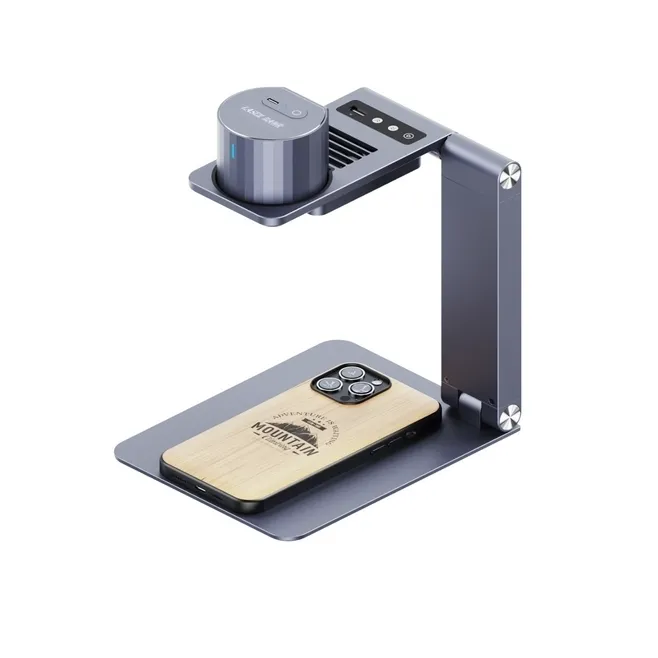

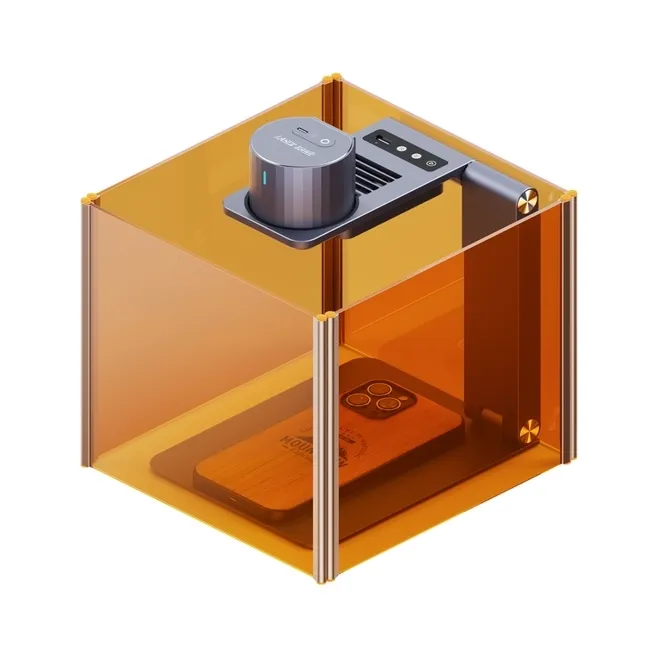

- Build Quality: Constructed from high-quality, durable materials, the LaserHawk LH1 Pro is built to withstand heavy use while maintaining accuracy and reliability.

- Software Compatibility: It supports popular laser engraving software such as LaserGRBL, Simplify3D, and Fusion 360, ensuring seamless integration with your existing workflow.

- Material Compatibility: The LaserHawk LH1 Pro can engrave and cut materials like wood, metal, plastic, acrylic, leather, and fabric.

- Resolution: With a high-resolution laser beam, it achieves detailed engravings and clean cuts, making it ideal for intricate designs.

- User Interface: Equipped with an intuitive control panel, the machine is easy to operate, even for those new to laser engraving.

These specifications highlight the LaserHawk LH1 Pro’s ability to handle both small-scale projects and industrial-level production, making it a versatile tool for various applications.

Key Features of the LaserHawk LH1 Pro

Precision Engraving and Cutting

One of the standout features of the LaserHawk LH1 Pro is its ability to deliver precise engravings and cuts. The high-powered laser ensures that even the most intricate designs are rendered with clarity and accuracy, making it a favorite among artists and craftsmen.

Versatility in Material Handling

The machine’s compatibility with multiple materials makes it an excellent choice for diverse projects. Whether you’re working with wood, metal, or acrylic, the LaserHawk LH1 Pro can handle it with ease, providing consistent results across different surfaces.

User-Friendly Design

Designed with both professionals and beginners in mind, the LaserHawk LH1 Pro features an easy-to-use interface that simplifies operation. Its intuitive controls allow users to adjust settings such as laser power, speed, and focus without requiring extensive technical knowledge.

Durability and Reliability

Constructed with high-quality components, the machine is built to last. Its robust build ensures long-term durability, making it a worthwhile investment for those looking for a reliable laser engraver.

Applications of the LaserHawk LH1 Pro

The LaserHawk LH1 Pro finds its niche in various industries and creative fields:

Artistic Engraving

Artists can use this machine to create detailed engravings on wood, metal, and other materials, bringing their designs to life with precision.

Custom Jewelry Making

Jewelers often rely on laser engravers for creating personalized engravings on metals like stainless steel, titanium, and gold. The LaserHawk LH1 Pro excels in this area, offering clean cuts and sharp engravings.

Prototyping and Small-Scale Manufacturing

For manufacturers, the machine serves as an efficient tool for prototyping and producing small batches of products, ensuring quick turnaround times without compromising quality.

Industrial Applications

In industrial settings, the LaserHawk LH1 Pro is used for cutting and engraving materials like plastic and metal components, contributing to large-scale production processes.

Advantages of the LaserHawk LH1 Pro

The LaserHawk LH1 Pro offers several advantages that set it apart from other laser engravers:

High Precision

Its advanced laser technology ensures precise cuts and engravings, minimizing errors and waste.

Cost-Effective

Despite its high performance, the machine is relatively affordable compared to other professional-grade laser engravers, making it accessible for small businesses and hobbyists.

Ease of Maintenance

The LaserHawk LH1 Pro requires minimal maintenance, with components that are easy to clean and replace. This ensures long-term functionality and reduces downtime.

Customization Options

Users can customize the machine’s settings to suit their specific project needs, providing flexibility in operation.

FAQs About the LaserHawk LH1 Pro

Here are some frequently asked questions about the LaserHawk LH1 Pro:

1. What materials can the LaserHawk LH1 Pro engrave and cut?

The machine is compatible with a wide range of materials, including wood, metal, plastic, acrylic, leather, and fabric. Its versatility makes it suitable for various projects.

2. Is the LaserHawk LH1 Pro easy to use?

Yes, the machine features an intuitive interface that simplifies operation. Even users with limited experience can quickly learn how to use it effectively.

3. What are the maintenance requirements for this laser engraver?

The LaserHawk LH1 Pro requires minimal maintenance, primarily involving cleaning the lens and ensuring proper ventilation during operation.

4. Can it handle large-scale projects?

While it is excellent for small to medium-sized projects, the machine may require additional setup or modifications for very large-scale applications.

5. Is the LaserHawk LH1 Pro suitable for industrial use?

Yes, its robust build and high-performance capabilities make it ideal for industrial applications, including prototyping and component manufacturing.

Conclusion

The LaserHawk LH1 Pro is a powerful tool that combines precision, versatility, and ease of use, making it a valuable addition to any workshop or production facility. Whether you’re an artist, jeweler, or manufacturer, this laser engraver offers the performance and flexibility needed to bring your projects to life. Its affordability and durability further enhance its appeal, solidifying its position as one of the top choices in the market.

If you’re considering investing in a laser engraver, the LaserHawk LH1 Pro is definitely worth exploring for its exceptional capabilities and user-friendly design.

Jin Johnson –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are top-notch. Operation and software are user-friendly. Fast speed boosts efficiency. Well-built and reliable!

Juan Garcia –

As a laser engraver user, I give this machine 5 stars! The engraving effects are crisp, precise. The operation is smooth, software intuitive. Fast, efficient, solidly built, reliable.

Soo Martinez –

Five stars for this laser engraver! The engraving effects are crisp and precise. The machine is intuitive, and the software is user-friendly. Fast speeds boost my productivity. Sturdy build, highly reliable.

Miguel Tanaka –

Absolutely stunning engraving results with pinpoint accuracy! The machine is a breeze to operate, and the software is intuitive. Fast speeds boost productivity, while robust build ensures reliability. 5 stars!

Barbara Bernard –

As a laser engraver user, I give this machine 5 stars! The engraving results are stunningly precise. The software is intuitive, and operations are seamless. Fast engraving speed boosts overall productivity. Solid build, highly reliable!

Jose Smith (verified owner) –

**Performance & User Experience Review:**

The 40W CO2 laser engraver excels in wood and acrylic, delivering 0.1mm precision at 500mm/s. Engraved birch plywood coasters showed crisp, burn-free details, while 3mm acrylic signs had polished edges. Leather required power adjustments to avoid overburn. Setup was intuitive, but aligning the honeycomb bed took trial and error. LightBurn software’s layer-based workflow streamlined complex designs, though beginners might find the advanced settings overwhelming. The autofocus feature saved time during material swaps. Minor gripe: the 300x200mm workspace limits larger projects. Ideal for small businesses needing detail-focused output without industrial costs.

Carmen Romano (verified owner) –

The laser engraver demonstrates exceptional performance across various materials. For wood projects, intricate details are rendered precisely with minimal burn, while acrylic engravings benefit from high-speed settings without cracking. Leather work is consistently clean, thanks to an adjustable focus lens. Setup is straightforward with clear instructions, though mastering advanced features requires some learning. The user-friendly software interface occasionally lags on complex designs but offers preloaded templates and customization options. Overall, this tool provides excellent value, balancing cost-effectiveness with a good ROI for personal and business use, despite minor customer support gaps.

Otto Baker (verified owner) –

The laser engraver excels in Performance Analysis across materials like wood, acrylic, and leather, delivering crisp details on custom signs and engraved jewelry. Its precision and speed are impressive, though minor delays occur with complex files. User Experience is seamless; the intuitive software simplifies setup, and features like vector file import enhance workflow efficiency. Compared to competitors, it offers superior engraving quality at a competitive price, making it ideal for both small businesses and hobbyists seeking reliable performance.

Hye Han (verified owner) –

The laser engraver excels in performance across materials like wood, acrylic, and leather, delivering crisp engravings at high precision. Its 40W power ensures smooth cuts and detailed etches, ideal for intricate designs. The software interface is user-friendly, with intuitive controls that even beginners can master quickly. However, the learning curve could benefit from more guided tutorials. For businesses, its fast processing speeds and large workspace make it suitable for high-volume projects. While it offers excellent value, additional safety features would enhance long-term reliability. Overall, a robust choice for artistic and commercial use, balancing performance and affordability effectively.

Ming Nelson (verified owner) –

**Technical Performance:**

The laser engraver has demonstrated exceptional power and precision, enabling intricate detailing on materials like acrylic, wood, and metal. The software is user-friendly and integrates seamlessly with our design workflow, allowing precise control over depth and speed. Features such as vector cutting have proven invaluable for creating clean lines and complex patterns, enhancing the quality of our trophy designs.

**Business Impact:**

The engraver has significantly improved our workflow by reducing production time and enabling more detailed designs. Customer feedback has been overwhelmingly positive, with clients appreciating the enhanced quality and faster turnaround times. The return on investment is evident through increased orders and a stronger market reputation, solidifying our position as leaders in custom trophy manufacturing.