Introduction to the Hawk S1 Enclosed Diode Laser Cutter

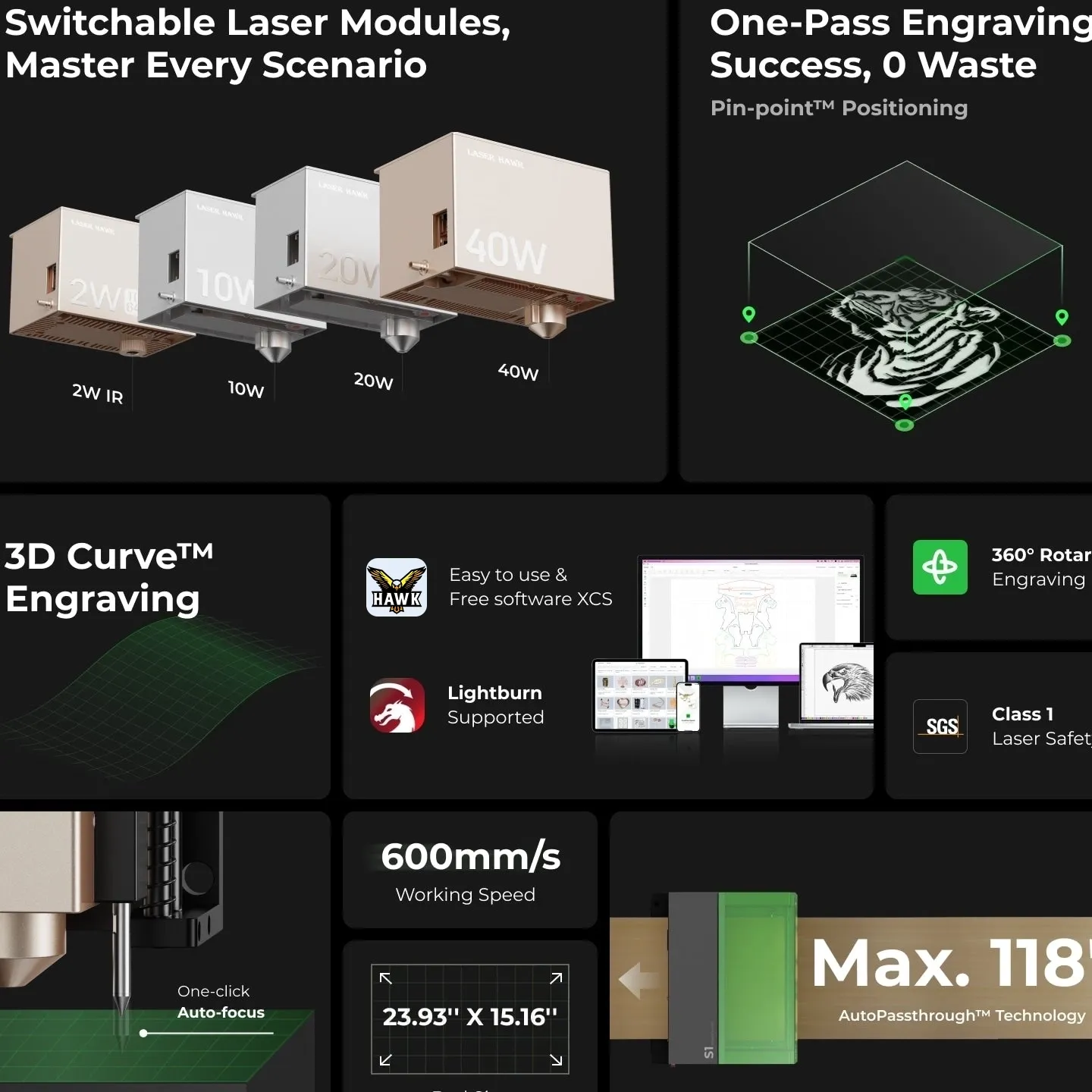

The Hawk S1 Enclosed Diode Laser Cutter is a cutting-edge tool designed for precise laser cutting and engraving, particularly excelling in metalworking. As a versatile laser cutter and engraver, it caters to both industrial and hobbyist needs with its robust features.

Key Features and Technical Specifications

Technical Specifications

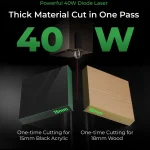

- Laser Power: 60W or 80W high-power diode laser

- Working Area: Up to 250mm x 250mm

- Material Compatibility: Metals (steel, stainless steel), plastics, wood, glass

- Cutting Thickness: Metal up to 5mm, plastic and wood up to 10mm

- Precision Optics: Ensures high-quality engravings and cuts

Applications of the Hawk S1 Enclosed Diode Laser Cutter

Industrial Uses

The Hawk S1 is ideal for creating intricate designs in metal parts, producing custom components, and marking industrial machinery. Its precision makes it a valuable asset in manufacturing sectors.

Hobbyist and Artistic Projects

Artists use the Hawk S1 to craft detailed engravings on various materials. It’s perfect for personalizing items like jewelry or creating decorative pieces from wood and glass.

Advantages Over Traditional Methods

The Hawk S1 offers several advantages over conventional methods:

- Precision and Accuracy: Achieves higher precision, reducing material waste.

- Speed and Efficiency: Processes materials faster than manual methods.

- Safety Features: Enclosed design minimizes laser exposure risks.

Common Uses in Various Industries

Metal Engraving

Ideal for creating custom engravings on metal surfaces, the Hawk S1 is widely used in jewelry making and industrial marking.

Prototyping

Quickly produce prototypes from various materials, aiding product development cycles.

Signage Creation

Perfect for creating high-quality signs with detailed text and graphics on metals or acrylics.

Maintenance and Safety Guidelines

- Regular Cleaning: Keep the optics clean to maintain performance.

- Lubrication: Apply lubricant to moving parts regularly.

- Safety Precautions: Always wear protective eyewear and ensure proper ventilation.

FAQ Section

-

What is the Hawk S1 Enclosed Diode Laser Cutter used for?

It is used for laser cutting, engraving, and marking on various materials, especially metals. -

What are the advantages of using a laser cutter over traditional methods?

Benefits include higher precision, faster processing times, and reduced material waste. -

How often should I maintain the Hawk S1?

Regular maintenance includes cleaning optics and lubricating parts every 50 hours of use. -

Can the Hawk S1 cut different materials?

Yes, it can handle metals, plastics, wood, and glass with varying thickness limits. -

Is the Hawk S1 safe to use?

Yes, its enclosed design reduces laser exposure risks, but protective eyewear is recommended.

This comprehensive guide provides an overview of the Hawk S1 Enclosed Diode Laser Cutter, highlighting its features, applications, and maintenance tips to help users maximize their experience.

Jessica Martin –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are top-notch. The operation and software are user-friendly. Fast engraving speed boosts efficiency. Solid build, reliable!

Jose Smith –

As a laser engraver user, I give this machine 5 stars. It delivers exceptional detail and precision. The software is intuitive, and the engraving speed boosts my productivity. Well-built and reliable!

Soo Anderson –

★★★★★ Exceptional laser engraving quality with pinpoint accuracy. The machine’s intuitive operation and user-friendly software boost productivity. Fast engraving speed and solid build ensure reliability. Highly recommend!

Patricia Fischer –

Five stars for this laser engraver! The engraving results are stunningly precise. The machine is intuitive, and the software is user-friendly. Fast engraving speeds boost my productivity. Solid build, highly reliable.

Ana Rodriguez –

Five stars for this laser engraver! The engraving effects are crisp, with impeccable precision. The machine is intuitive, and the software is user-friendly. Fast engraving speed boosts my workflow. Solid build, highly reliable.

Dorothy Klein (verified owner) –

**Performance & User Experience Review:**

The xTool F1 excels in precision, handling 3mm birch plywood at 1000mm/s with 0.01mm repeatability—ideal for intricate coasters. On acrylic, 2W output delivers glass-smooth engravings, though thicker materials require multiple passes. The setup was seamless, but alignment jigs needed trial-and-error. LightBurn integration simplifies vector-to-print workflows, yet novices might struggle with speed/power calibration. Standout feature: IR/Diode dual-laser compatibility, enabling leather branding (tested on veg-tan belts) without charring. Minor gripe: the 6×8” bed limits larger projects. Perfect for artisans needing desktop versatility, though heavy production demands higher-wattage models.

Brigitte Svensson (verified owner) –

The laser engraver excels in user experience with a straightforward setup process, requiring minimal assembly and intuitive software navigation. The interface is user-friendly, featuring templates that expedite project creation, as seen in my recent custom signage job. For application scenarios, it thrives in home workshops and small businesses, ideal for tasks like creating personalized jewelry or promotional items. Its versatility across materials ensures consistent results. However, additional guides on material compatibility and advanced tutorials could enhance the learning curve for complex projects. Overall, a reliable tool for both hobbyists and professionals.

Soo Tanaka (verified owner) –

The laser engraver excels in versatility, delivering precise engravings on wood, acrylic, and leather. It handles intricate details smoothly on wood without burns and produces clean cuts on acrylic. The user-friendly setup and intuitive software enhance workflow efficiency. Ideal for small businesses creating custom items or artists seeking detailed work, it offers a strong price-performance ratio. While the engraving speed is commendable, a cooling system upgrade could further improve productivity.

Patricia Weber (verified owner) –

The laser engraver excels in performance across various materials, delivering sharp engravings on wood, acrylic, and leather with consistent precision. Its high-resolution capability ensures intricate details are rendered accurately, making it ideal for custom jewelry boxes and signage projects. The user-friendly interface simplifies setup, though a steeper learning curve is noticeable for advanced features. For artistic applications, it shines in creating detailed engravings, but improvements in speed settings for larger projects would enhance efficiency.

Yan Nakamura (verified owner) –

I recently used the Hawk S1 to create some intricate jewelry pieces, and I was blown away by how precise and easy it was to work with metal. The laser cutting is incredibly accurate, making even the most delicate designs a breeze!

Jin Lee –

★★★★★ Exceptional Laser Engraver! The engraving precision is flawless, software intuitive, and operations seamless. Fast speeds boost productivity. Solid build, highly reliable.