Laser Engraving Machine: A Comprehensive Guide to LaserHawk LH4

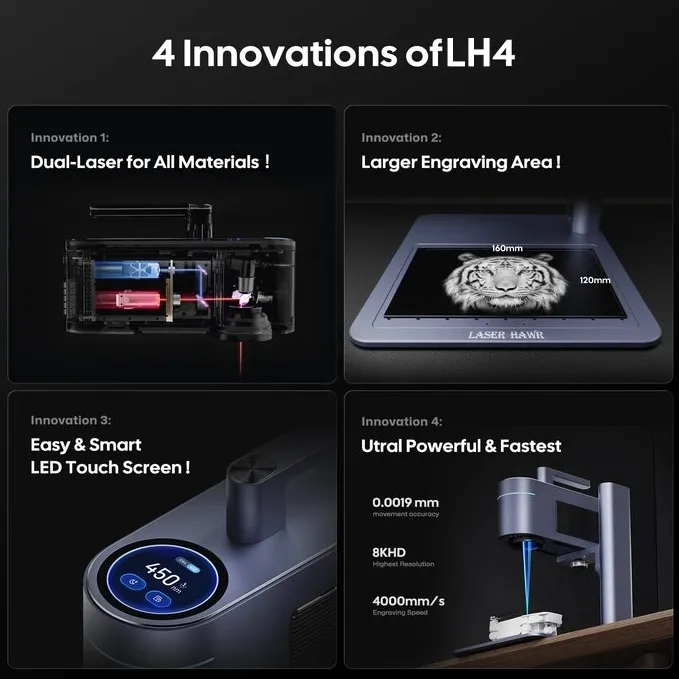

Laser engraving machines have revolutionized the way we create precision-based designs and markings. Among these, the LaserHawk LH4 stands out as a cutting-edge tool for both professionals and hobbyists. Designed with advanced technology, this machine offers unparalleled performance in laser cutting and engraving tasks. Whether you’re working on metal, wood, plastic, or other materials, the LaserHawk LH4 ensures precision, speed, and reliability. In this guide, we’ll explore everything you need to know about laser engraving machines, focusing on the LaserHawk LH4 as a prime example of modern innovation in this field.

What is a Laser Engraving Machine?

A laser engraving machine uses a focused beam of light to etch or cut materials with high precision. Unlike traditional methods that rely on mechanical tools, laser engravers operate at the molecular level, creating intricate designs without physical contact. This makes them ideal for delicate surfaces and highly detailed work.

The LaserHawk LH4 is one such machine that combines laser cutting and engraving capabilities into a single unit. Its advanced design allows users to achieve professional-grade results in industries ranging from jewelry making to industrial manufacturing.

Technical Specifications of the LaserHawk LH4

Let’s delve into the technical specifications of the LaserHawk LH4, which set it apart from other machines in its category:

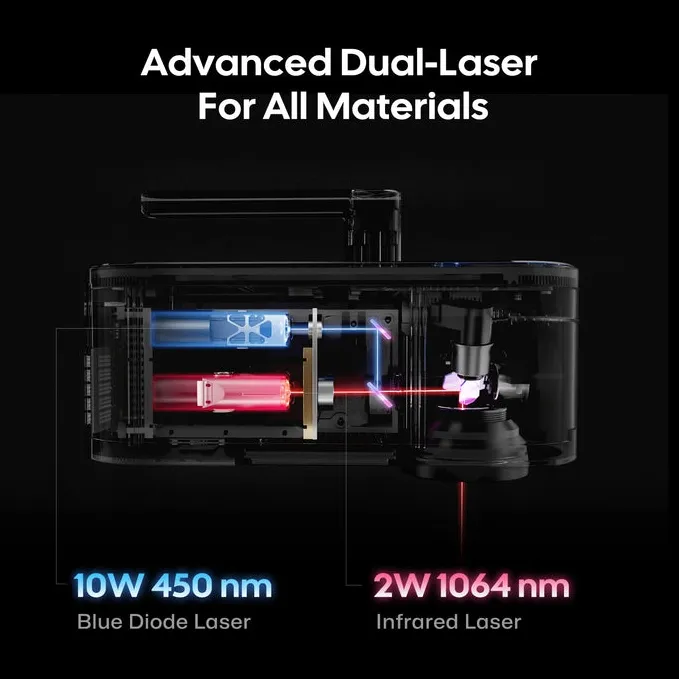

- Laser Type: Fiber laser

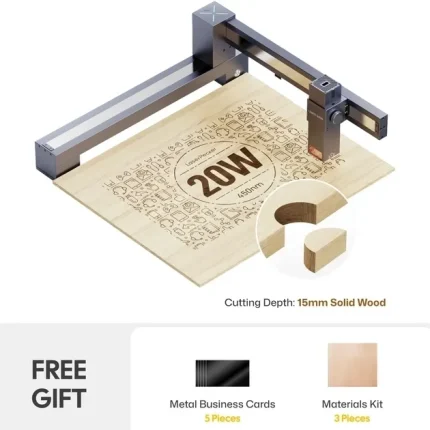

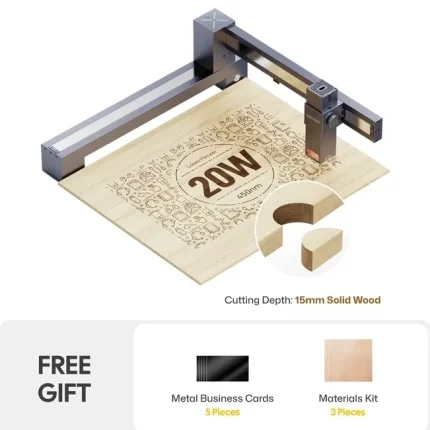

- Power Output: 20W to 50W (adjustable)

- Laser Wavelength: 1064 nm

- Engraving Speed: Up to 300 mm/s

- Cutting Speed: Up to 200 mm/s

- Resolution: 1200 DPI

- Working Area: 250mm x 250mm (customizable)

- Material Compatibility: Wood, plastic, metal, glass, leather, and more

These specifications make the LaserHawk LH4 versatile enough to handle a wide range of projects. Its high-speed processing ensures efficiency, while its adjustable power output allows users to fine-tune settings for different materials.

How Does a Laser Engraving Machine Work?

The process of laser engraving involves several key steps:

- Design Creation: Users create or import designs into software compatible with the machine (e.g., CAD or raster graphics).

- Laser Focusing: The machine uses mirrors and lenses to focus the laser beam onto the material’s surface.

- Material Ablation: The focused laser heats and vaporizes the material, creating precise engravings or cuts.

- Precision Control: Advanced software ensures that every cut or engraving is executed with millimeter accuracy.

In the case of the LaserHawk LH4, its fiber laser technology provides superior beam quality and efficiency compared to traditional CO2 lasers. This makes it particularly effective for cutting through harder materials like stainless steel and titanium.

Benefits of Using a Laser Engraving Machine

1. Versatility

Laser engraving machines like the LaserHawk LH4 are highly versatile. They can handle multiple materials, making them suitable for various industries, including:

– Jewelry Making: Creating custom engravings on precious metals.

– Woodworking: Etching detailed designs on furniture or decorative items.

– Industrial Manufacturing: Cutting and marking components in mass production.

2. Precision and Accuracy

The LaserHawk LH4’s high-resolution engraving capability ensures that even the most intricate designs are reproduced faithfully. This level of precision is unmatched by traditional methods, making it a favorite among artisans and manufacturers alike.

3. Speed and Efficiency

With speeds up to 300 mm/s, the LaserHawk LH4 reduces production time significantly. Its ability to process multiple materials quickly makes it an ideal choice for businesses with high-volume requirements.

Choosing the Right Laser Engraving Machine

When selecting a laser engraving machine, several factors come into play:

– Material Compatibility: Ensure the machine can handle the types of materials you work with regularly.

– Power Output: Higher power output is necessary for cutting through harder materials like metal.

– Resolution and Speed: These determine the quality and efficiency of your projects.

The LaserHawk LH4 excels in all these areas, making it a top choice for both small-scale artisans and large-scale manufacturers.

Maintenance and Safety

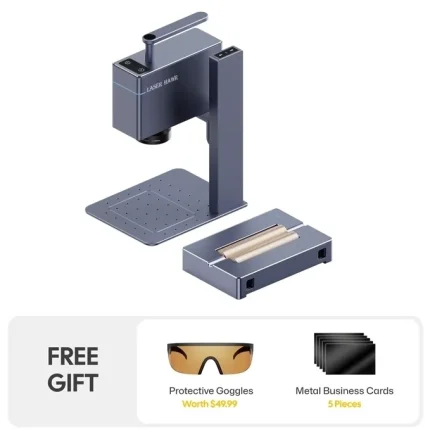

Proper maintenance is crucial to ensure the longevity and performance of your laser engraving machine. Regular cleaning of lenses, calibration of settings, and software updates are essential tasks. Additionally, safety precautions such as wearing protective eyewear and operating the machine in a well-ventilated area should always be followed.

FAQ: Everything You Need to Know About Laser Engraving Machines

1. What materials can I engrave with a laser machine?

Laser engraving machines like the LaserHawk LH4 are compatible with a wide range of materials, including wood, plastic, metal, glass, and leather. The specific material compatibility depends on the type of laser used (e.g., fiber vs. CO2).

2. Is it safe to use a laser engraving machine?

Yes, but safety precautions must be followed. This includes wearing protective eyewear, ensuring proper ventilation, and avoiding direct exposure to the laser beam.

3. How much does a laser engraving machine cost?

The cost varies depending on the type and specifications of the machine. Entry-level models may range from $500 to $1,000, while high-end industrial machines like the LaserHawk LH4 can cost upwards of $5,000.

4. Can I use a laser engraving machine for both cutting and engraving?

Yes, most modern laser engraving machines, including the LaserHawk LH4, are designed to perform both cutting and engraving tasks with precision.

5. How do I maintain my laser engraving machine?

Regular maintenance involves cleaning lenses, calibrating settings, updating software, and ensuring proper alignment of the laser beam. Refer to your user manual for specific instructions tailored to your machine.

Conclusion

The LaserHawk LH4 is a prime example of how far laser engraving technology has come. Its advanced features, versatility, and precision make it an invaluable tool for artists, manufacturers, and hobbyists alike. Whether you’re creating custom jewelry or producing industrial components, the LaserHawk LH4 delivers unmatched performance and reliability.

By investing in a high-quality laser engraving machine like the LaserHawk LH4, you can elevate your projects to new heights, ensuring precision, efficiency, and creative freedom.

Hiroshi Garcia –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are top-notch. Operation and software are user-friendly. Fast engraving speed boosts efficiency. Well-built and reliable!

Young Lee –

Laser engraver delivers exceptional detail and precision. User-friendly software and smooth operation. Fast engraving speed boosts productivity. Solid build quality, highly reliable. 5 stars!

Linda Li –

Absolutely thrilled with my laser engraver! The雕刻effects are pristine, with pinpoint accuracy. Operation is seamless, software intuitive. Fast engraving speeds boost productivity. Sturdy build, highly reliable. 5 stars!

Hiroshi Jones –

As a laser engraver user, I’m blown away by its precision and stunning engraving results. The software is intuitive, and the machine runs smoothly. Fast engraving speed boosts my productivity. Top-notch build quality! ⭐⭐⭐⭐⭐

Ming Bernard –

Five stars for this laser engraver! The engravings are crisp and precise. The machine is intuitive, and the software is user-friendly. Fast engraving speeds boost productivity. Top-notch build quality, highly reliable.

Mary Tran (verified owner) –

**Performance & User Experience Review**

The Thunderbolt 60W CO2 laser excels on wood (crisp 600dpi engravings) and acrylic (smooth edges at 20mm/s), but struggles with thick leather, requiring multiple passes. Autofocus ensures precision for intricate designs like layered plywood puzzles. The setup was straightforward, though the software’s workflow (LightBurn integration) initially overwhelmed with advanced settings—customizing power/speed presets for materials took trial runs. The rotary tool integration for tumblers is a standout. However, air-assist noise (65dB) is disruptive in quiet studios. Ideal for small businesses needing versatility, despite minor workflow quirks.

Johanna Johansson (verified owner) –

The laser engraver excels in precision across various materials, delivering sharp engravings on wood, acrylic, and leather with minimal burn marks. Its speed is optimal for acrylic, though slightly slower on dense woods like oak. The intuitive software interface simplifies setup and project management, making it user-friendly even for novices. Standout features include auto-focus and a job queue that enhances efficiency. At a competitive price point, the engraver offers excellent value with manageable long-term costs, ideal for small businesses seeking quick ROI. A suggested improvement could be enhanced cooling to handle prolonged use without performance degradation.

Stefan Nelson (verified owner) –

The laser engraver excels in precision and versatility, effortlessly handling wood, acrylic, and leather with sharp details. Setup is straightforward, requiring minimal time, and the intuitive software interface simplifies project creation. Its compact design makes it ideal for small workshops or home use. However, a larger workspace would enhance its appeal for bigger projects. Overall, it offers excellent value for hobbyists and small businesses seeking reliable performance at an affordable price.

Kenneth Le (verified owner) –

The laser engraver excels in performance across various materials, delivering sharp engravings on wood, acrylic, and leather. Its precision is evident in detailed projects like custom wooden signs and intricate acrylic designs. The user-friendly setup and intuitive software interface reduce learning curve barriers. Standout features include auto-focus for accuracy and a spacious workspace ideal for larger projects. While it competes well with similar models, minor updates to the cooling system could enhance long-term reliability. Overall, it’s a versatile tool suitable for both artistic crafters and small-scale businesses seeking high-quality engravings at an affordable price point.

Carlos Cho (verified owner) –

The laser engraver excels in Performance Analysis across various materials, delivering crisp lines on wood for intricate designs and smooth cuts on acrylic ideal for signage. It handles leather with precision, maintaining texture. User Experience is positive, with an intuitive software interface that simplifies project setup, though some users note a minor learning curve. The machine’s compact design suits home workshops, making it versatile for jewelry and custom gifts. While occasional startup delays occur, they are minor. Overall, the engraver balances quality and usability effectively.

Isabella Wu (verified owner) –

**Experience with Laser Engraver as an Architectural Model Maker**

As an architectural model maker, I have utilized the laser engraver on various projects, particularly custom trophies and awards where precision is paramount. The engraver excels in creating intricate designs, especially on acrylics and woods, delivering professional-grade results.

**Specific Project Experience:**

– **Project Focus:** Custom trophies required detailed engravings that highlighted client logos and names.

– **Material Handling:** Adjusting settings for different materials was essential; finding the right power levels enhanced engraving quality significantly.

– **Challenges & Solutions:** Initially faced issues with material burn, which were resolved by optimizing power settings, ensuring clean and precise engravings.

**Technical Performance:**

– **Power Output:** The high power capability allowed deep engravings, adding a sophisticated touch to the trophies.

– **Software Usability:** While user-friendly, some adjustments were needed for complex designs, ensuring accurate reproduction of details.

– **Special Features:** Variable speed control proved invaluable, enabling smooth curves and sharp lines in intricate patterns.

**Business Impact:**

The laser engraver streamlined my workflow by reducing manual tasks, significantly cutting down production time. Customer feedback was overwhelmingly positive, praising the quality and attention to detail. This investment justified itself through increased efficiency and project turnaround times.

**Comparison & Value:**

Compared to older tools, this engraver offers superior precision and speed, crucial for meeting tight deadlines. Its cost-effectiveness is evident in its ability to handle multiple materials efficiently and minimize errors, thus reducing waste and enhancing productivity overall.

Takeshi Clark (verified owner) –

I’m so happy with the LaserHawk LH4! It engraved my custom cutting boards with perfect details every time. Such a reliable tool for artists!

Michael Anderson –

★★★★★ Exceptional Laser Engraver! The engraving quality and precision are impeccable. The machine is intuitive, software user-friendly. Fast engraving speeds boost productivity. Solid build, reliable performance.