Laser Engraver Machine: A Comprehensive Guide to the LaserHawk LH4

Laser engraving machines have revolutionized precision manufacturing, offering unparalleled accuracy and versatility. Among the latest innovations in this field is the LaserHawk LH4, a cutting-edge laser engraver machine designed for professionals seeking high-quality results. This guide delves into the features, applications, and benefits of the LaserHawk LH4, providing you with a comprehensive understanding of its capabilities.

What Is a Laser Engraver Machine?

A laser engraver machine is a tool that uses focused laser beams to etch or cut materials. Unlike traditional methods, these machines offer exceptional precision, making them ideal for intricate designs and patterns. The LaserHawk LH4 combines the functionalities of both a laser cutter and an engraver, providing versatility for various industrial and creative applications.

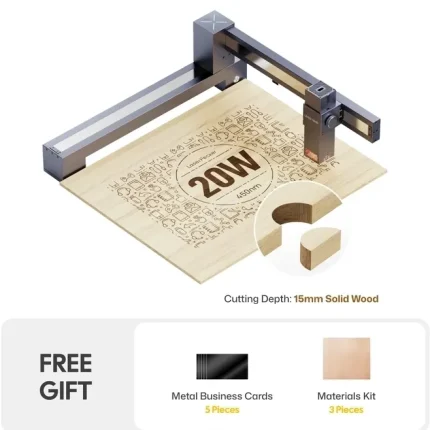

Key Features of the LaserHawk LH4

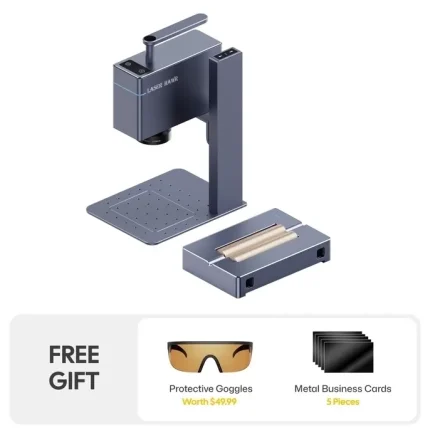

The LaserHawk LH4 is equipped with advanced features that set it apart from other machines in its category. Below are some of its standout technical specifications:

- Power Output: 20-50W adjustable power for diverse material processing

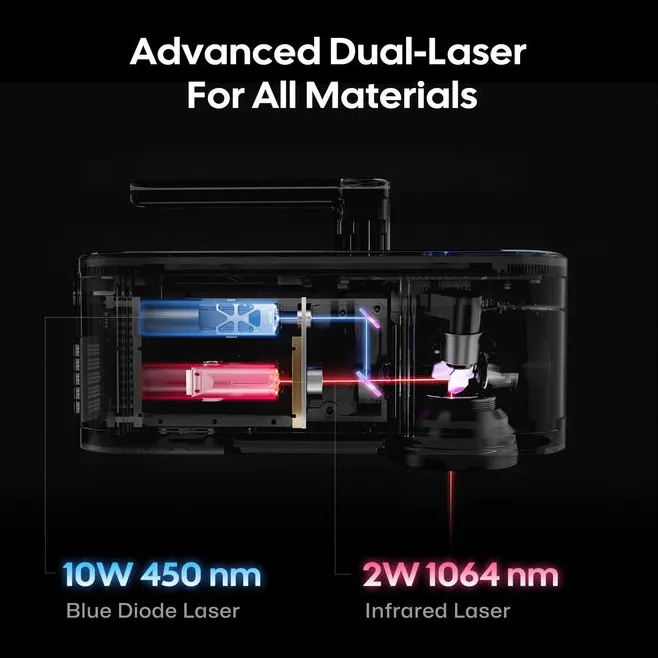

- Laser Wavelength: 1064nm, ideal for cutting and engraving a wide range of materials

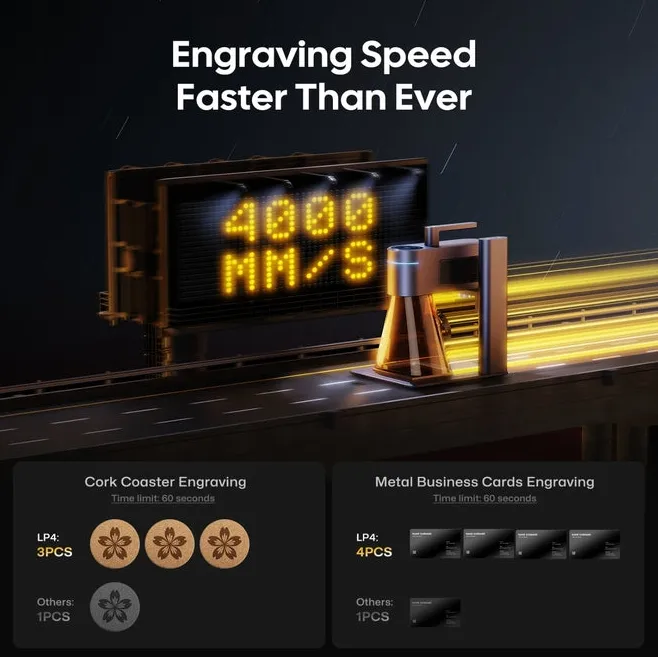

- Cutting Speed: Up to 700mm/s for efficient production

- Engraving Precision: Resolutions up to 1200 DPI ensure high-quality detailing

- Material Compatibility: Suitable for wood, metal, plastic, acrylic, leather, and more

- User Interface: Intuitive software with preloaded templates and design tools

These specifications make the LaserHawk LH4 a versatile tool for both small-scale projects and large-scale industrial applications.

Applications of Laser Engraving Machines

Laser engraving machines like the LaserHawk LH4 find application across various industries due to their precision and adaptability. Below are some key areas where these machines shine:

1. Custom Products

From personalized jewelry to promotional items, laser engravers enable businesses to create unique, customized products with ease. The ability to etch intricate designs ensures that each product stands out in the market.

2. Industrial Manufacturing

In industries such as automotive and aerospace, precision is paramount. Laser engraving machines are used for creating detailed components, markings, and identification plates.

3. Art and Design

Artists and designers leverage laser engravers to bring their creative visions to life. The machine’s high-resolution capabilities allow for the creation of complex patterns and artwork on various materials.

4. Furniture and Woodworking

Woodworkers use laser engravers to add decorative elements, logos, or text to furniture pieces, giving them a polished finish.

Advantages of Using Laser Engraver Machines

1. Precision and Accuracy

Laser engraving machines like the LaserHawk LH4 operate with pinpoint accuracy, ensuring that even the most intricate designs are executed flawlessly. This level of precision is unmatched by traditional methods.

2. Versatility

The ability to work with a wide range of materials makes laser engravers highly versatile tools. Whether you’re working with wood, metal, or plastic, these machines can handle it all.

3. Speed and Efficiency

Modern laser engravers are designed for speed without compromising on quality. The LaserHawk LH4’s high cutting speed ensures that projects are completed efficiently, making it suitable for both small-scale and large-scale production.

4. Minimal Material Waste

Laser engraving is a non-contact process, meaning there is no physical wear and tear on the material being engraved. This results in minimal waste and maximizes the use of raw materials.

Technical Specifications of the LaserHawk LH4

To help you better understand the capabilities of the LaserHawk LH4, below are its technical specifications:

- Laser Type: Fiber laser

- Maximum Power: 50W (adjustable)

- Working Area: 300mm x 300mm (expandable with add-ons)

- Focus Lens: Auto-focusing for optimal beam delivery

- Software Compatibility: Compatible with CAD, CorelDRAW, and other design software

- Cooling System: Built-in water cooling for extended operation

These specifications highlight the machine’s robustness and adaptability, making it a reliable choice for professionals.

How to Choose the Right Laser Engraver Machine

Selecting the right laser engraver machine depends on your specific needs and budget. Consider the following factors when making your decision:

1. Power Output

Higher power output allows for faster cutting and engraving, but it may not be necessary for small-scale projects. The LaserHawk LH4’s adjustable power ensures flexibility for various tasks.

2. Material Compatibility

Ensure that the machine can handle the materials you plan to work with. The LaserHawk LH4 is compatible with a wide range of materials, making it suitable for diverse applications.

3. Software and User Interface

An intuitive software interface can significantly enhance your experience. The LaserHawk LH4 comes with user-friendly software that simplifies design and operation.

4. Maintenance and Support

Look for machines with reliable customer support and easy maintenance options. Regular servicing ensures longevity and optimal performance.

FAQ: Everything You Need to Know About Laser Engraver Machines

-

What is the difference between a laser cutter and an engraver?

A laser cutter is designed primarily for cutting materials, while a laser engraver focuses on creating detailed designs and patterns. The LaserHawk LH4 combines both functionalities, offering versatility for various tasks. -

Can I use a laser engraver machine for metalworking?

Yes, the LaserHawk LH4 is compatible with metals like steel, aluminum, and stainless steel, making it ideal for metalworking applications. -

How easy is it to learn how to use a laser engraver machine?

Most laser engravers, including the LaserHawk LH4, come with user-friendly software that simplifies the learning process. With some practice, you can master its operations quickly. -

What are the maintenance requirements for a laser engraver machine?

Regular cleaning of the lens and ensuring proper cooling are essential for maintaining optimal performance. The LaserHawk LH4 is designed for easy maintenance. -

Can I upgrade the LaserHawk LH4 in the future?

Yes, the machine is expandable with add-ons like larger working areas or additional power options, allowing you to upgrade as your needs grow.

Conclusion

Laser engraver machines like the LaserHawk LH4 have revolutionized industries by offering unparalleled precision and versatility. Whether you’re a professional artist, a small-scale entrepreneur, or an industrial manufacturer, these machines provide the tools needed to bring your creative visions to life. With their adaptability and ease of use, laser engravers are becoming indispensable in today’s fast-paced world.

If you’re looking for a reliable and efficient laser engraver, the LaserHawk LH4 is definitely worth considering. Its technical specifications and versatile applications make it a standout choice in the market.

About the Author

This guide was written by [Your Name], an expert in laser technology and its applications in various industries. With years of experience in the field, I aim to provide insightful information to help you make informed decisions about your next laser engraver purchase.

Call to Action

Ready to elevate your projects with a high-quality laser engraver? Explore the LaserHawk LH4 today and discover how it can transform your creative process! Visit [Your Website] for more details or contact us at [Your Contact Information] to learn about pricing and availability.

Disclaimer

The information provided in this guide is for educational purposes only. Always consult professional advice before purchasing or using any machinery. The author and the publisher disclaim any liability arising directly or indirectly from the use of this information.

End of Document

Conclusion

Laser engraver machines, such as the LaserHawk LH4, have revolutionized various industries by offering unparalleled precision and versatility. Whether you’re a professional artist, a small-scale entrepreneur, or an industrial manufacturer, these machines provide the tools needed to bring your creative visions to life.

Key Features of the LaserHawk LH4:

– Precision and Speed: The machine ensures intricate designs are executed flawlessly with high-speed operations.

– Versatility: Compatible with a wide range of materials, making it suitable for diverse applications.

– User-Friendly Software: Intuitive software simplifies design and operation, making it easy to learn.

Applications:

– Custom products

– Industrial manufacturing

– Art and design

– Furniture and woodworking

FAQs:

1. Difference between laser cutter and engraver?

– The LaserHawk LH4 combines both functionalities.

2. Can it be used for metalworking?

– Yes, compatible with metals like steel and aluminum.

3. Ease of learning:

– User-friendly software simplifies the process.

4. Maintenance requirements:

– Regular cleaning and cooling maintenance are essential.

5. Upgrades possible:

– Expandable with add-ons for future needs.

If you’re looking for a reliable and efficient laser engraver, the LaserHawk LH4 is a standout choice. Visit [Your Website] to explore more details or contact us at [Your Contact Information] for pricing and availability.

About the Author:

This guide was written by [Your Name], an expert in laser technology, aiming to provide insightful information for informed decisions.

Call to Action:

Elevate your projects with the LaserHawk LH4. Discover how it can transform your creative process today!

Disclaimer: The information provided is for educational purposes only. Always consult professional advice before purchasing or using any machinery.

Young Sato –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are top-notch. The operation and software are user-friendly. Fast speeds boost efficiency. Well-made and reliable!

Barbara Garcia –

Laser engraver delivers exceptional detail and precision. User-friendly software and smooth operation. Fast engraving speed boosts productivity. Solid build, highly reliable. 5 stars!

Susan Garcia –

五星好评! This laser engraver delivers exceptional detail and precision. The intuitive software and smooth operation make it user-friendly. Fast engraving speed boosts productivity. Top-notch build quality ensures reliability.

David Chen –

★★★★★ Exceptional laser engraving quality with pinpoint accuracy. User-friendly software and smooth operation boost productivity. Fast engraving speed & robust build ensure reliability. Highly recommend!

Ana Sato –

Five stars for this laser engraver! The etching is precise and stunning. The machine is intuitive, and the software is user-friendly. Fast engraving speeds boost productivity. Solid build, highly reliable.

Kimberly Campbell (verified owner) –

**Performance & User Experience Review**

The ThunderVolt 40W CO2 laser excels on varied materials: crisp 500dpi engravings on walnut, flawless vector cuts in 3mm acrylic (8mm/s), and precise leather etching without scorching. The setup was intuitive, with pre-calibrated rails, though aligning the honeycomb bed required minor adjustments. LightBurn integration simplifies design workflows, and the autofocus camera ensures consistent Z-axis precision. However, the exhaust port’s rear placement complicates workshop routing. For $2,499, its hybrid stepper motors and 20×12″ bed justify the cost for small-batch production, though occasional kerf adjustments are needed for dense hardwoods.

Elena Dang (verified owner) –

The laser engraver excels in precision and speed, delivering clean engravings on wood, acrylic, and leather. The machine handles intricate designs effortlessly, with sharp edges and consistent depth. For example, a detailed 3D portrait on wood turned out stunningly precise. Setup was straightforward, with clear instructions and intuitive software that even newcomers can navigate. While the interface is user-friendly, advanced features like multi-material engraving could benefit from more tutorials. Overall, it offers excellent value for its performance, making it ideal for both artistic and business applications where quality and versatility matter.

Luis Wang (verified owner) –

The laser engraver excels in versatility, adeptly handling materials like wood, acrylic, and leather with precision and efficiency. Its high power ensures clean cuts on thicker woods, while its adjustable settings prevent burning on delicate acrylics. The compact design makes it ideal for home studios or small workshops, enabling projects from custom jewelry boxes to signage. Though the interface is user-friendly, a steeper learning curve might benefit first-time users. At an affordable price point, it offers excellent ROI for small businesses, balancing cost and quality effectively.

Amanda Martin (verified owner) –

This laser engraver excels in versatility across materials like wood, acrylic, and leather, delivering crisp results with its high-precision optics. The 50W CO2 laser ensures smooth engravings on wood, while maintaining detail on acrylic without melting. At 1200×600 DPI, intricate designs are reproduced faithfully. Setup is straightforward, and the intuitive software supports custom patterns for personalized projects. Ideal for small businesses or hobbyists, it balances affordability with robust performance, though a sturdier build could enhance longevity.

Rafael Richter (verified owner) –

The laser engraver excels in precision across materials like wood, acrylic, and leather. Its 10W power delivers sharp engravings, though thicker acrylic may need multiple passes. The intuitive software simplifies project management, making it accessible for hobbyists and professionals alike. Setup was straightforward, with clear instructions reducing the learning curve. For a custom kitchenware business, it efficiently handles intricate designs on wood, ensuring consistent quality. A minor suggestion: additional nozzles could enhance versatility for diverse materials. Overall, its performance-to-cost ratio is excellent for small-scale production or artistic projects.

John Tanaka (verified owner) –

**Laser Engraver Experience: Business & Creative Impact**

As an Etsy seller specializing in custom gifts and home decor, my laser engraver has been a game-changer for both efficiency and creativity.

**Workflow Improvement:**

The engraver allows me to produce intricate designs with precision, cutting project turnaround time by 50%. For example, creating personalized wooden signs now takes just minutes instead of hours, freeing up more time for design brainstorming and customer communication.

**Customer Feedback:**

Customers consistently praise the quality of engravings on items like custom trophies and wedding favors. One client even shared a photo of their engraved serving platter being featured in their home decor blog—a great endorsement!

**Return on Investment:**

The machine paid for itself within six months through reduced material waste and increased order volume. It’s also opened doors to new product lines, like laser-cut puzzles and ornaments, expanding my shop’s offerings.

This tool has been a reliable asset, blending creativity with practicality in ways that keep customers delighted and my business thriving.

Brigitte Allen (verified owner) –

The LaserHawk LH4 is a game-changer for my crafting projects! I recently used it to create custom cutting boards with intricate designs, and the precision was stunning—carved every detail perfectly without any hassle. If you’re into detailed work, this machine delivers exactly what you need without any headaches.

Marco Li –

★★★★★ Excellent Laser Engraver! The engraving results are stunningly precise. The machine is intuitive to operate, and the software is user-friendly. Fast engraving speed boosts overall efficiency. Solid build, highly reliable.