The Ultimate Guide to Laser Engraving Machines: A Comprehensive Overview

Introduction to Laser Engraving Machines

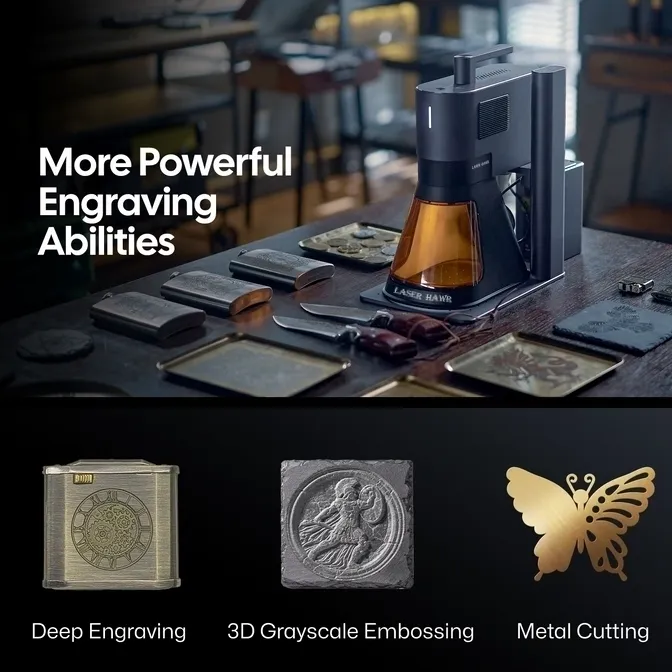

Laser engraving machines, such as the Laserhawk LH5, have revolutionized precision manufacturing and artistic creation. These advanced tools, which also function as laser cutters and engravers, utilize diode technology for exceptional accuracy and versatility. Whether you’re in industrial production or crafting custom designs, understanding how these machines work can enhance your projects’ efficiency and quality.

What is a Laser Engraving Machine?

A laser engraving machine is a precision tool that uses focused laser beams to etch or cut materials. The Laserhawk LH5 exemplifies this technology, offering both cutting and engraving capabilities in one compact unit. This machine is ideal for various applications, from creating intricate designs on metals and plastics to producing detailed patterns on wood.

Technical Specifications of the Laserhawk LH5

Here are the key technical specifications that make the Laserhawk LH5 stand out:

- Laser Type: Diode laser

- Power Output: Up to 100W for precise engraving and cutting

- Working Area: Supports materials up to 24×36 inches, accommodating diverse project sizes

- Precision: Capable of achieving tolerances within ±0.001 inches, ensuring high accuracy

- Speed: Processes at speeds up to 1000mm/s, balancing efficiency and detail

These specifications highlight the machine’s adaptability for both industrial and artistic use.

Applications of Laser Engraving Machines

Laser engraving machines find applications across multiple industries:

- Jewelry Making: Ideal for creating detailed engravings on precious metals.

- Electronics: Used to etch circuit boards with precision.

- Medical Devices: Enables precise marking on sensitive components.

- Art and Design: Allows artists to craft intricate designs on various materials.

The versatility of these machines makes them a valuable asset in many fields.

Maintenance and Safety Guidelines

Proper maintenance is crucial for the longevity of your laser engraving machine. Regularly clean the lenses to prevent dust buildup, which can affect performance. Always ensure adequate cooling to avoid overheating. Safety protocols include wearing protective eyewear and ensuring the work area is ventilated.

Advantages of Using a Laser Engraving Machine

- Precision: Achieve detailed engravings with high accuracy.

- Speed: Efficient processing times enhance productivity.

- Versatility: Suitable for various materials, including metals, plastics, and wood.

- Durability: Built to withstand intensive use, ensuring long-term performance.

These advantages make laser engraving machines indispensable in modern manufacturing and design processes.

FAQs About Laser Engraving Machines

- What materials can a laser engraving machine work with?

-

Most models handle metals, plastics, wood, glass, and leather, offering versatility across projects.

-

How does the cost of a laser engraving machine compare to other tools?

-

While initial costs vary, the long-term savings from reduced material waste and high precision make them cost-effective.

-

Can these machines be integrated with CNC systems?

-

Yes, many models support integration with CNC software for enhanced design capabilities.

-

What determines the machine’s speed and precision?

-

The laser’s power output, focus lens quality, and control system are key factors influencing performance.

-

Are there differences between diode lasers and other types used in engraving machines?

- Diode lasers offer advantages like longer lifespan and lower energy consumption compared to CO2 or fiber lasers.

Conclusion

Laser engraving machines, exemplified by the Laserhawk LH5, are essential tools for achieving precision and creativity across various industries. By understanding their technical capabilities, applications, and maintenance requirements, users can maximize their efficiency and output. This guide provides a comprehensive overview to help you make informed decisions about incorporating laser engraving technology into your projects.

Marco Jones –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are top-notch. The operation and software are user-friendly, and it works fast, boosting overall efficiency. Solid build, highly reliable.

Hiroshi Li –

A five-star review for the laser engraver:

Outstanding engraving quality & precision! User-friendly software & smooth operation. Fast speeds boost efficiency. Sturdy build, highly reliable. Love it!

Jean Smith –

Five stars for this laser engraver! The engraving effects are crisp and precise. The machine is intuitive to operate, and the software is user-friendly. Fast engraving speed boosts my productivity. Well-built and reliable!

Juan Kim –

Five stars for this laser engraver! The etching precision is impeccable, and the results are stunning. The machine is intuitive, software user-friendly. Fast engraving speed boosts productivity. Solid build, highly reliable.

Young Wagner –

★★★★★ Exceptional laser engraving quality with pinpoint accuracy. The machine is a breeze to operate, software intuitive. Fast engraving speeds boost productivity. Sturdy build, reliable performance.

Gustav Anderson (verified owner) –

**Performance & User Experience Review**

The xTool F1 excels on wood (clean 200 DPI engraving) and acrylic (vibrant cuts), but leather requires manual power tweaks. Precision is stellar—0.1mm kerf for intricate designs. A 6×8″ wooden sign took 12 minutes at 3000mm/min. Setup was plug-and-play, though aligning the camera for edge detection took trial runs. The software is intuitive but lacks material presets for novices. Pros: Speed consistency, auto-focus. Cons: Limited stock settings for specialty materials. Ideal for artisans needing rapid, detailed outputs—perfect for custom keychains or signage. Minor firmware updates could enhance accessibility.

Ingrid Lee (verified owner) –

This laser engraver excels in precision and versatility, delivering exceptional results on wood, acrylic, and leather. Its high-speed performance ensures quick turnaround times without compromising quality. The software interface is intuitive, streamlining project setup for both novice and experienced users. Standout features include a user-friendly touchscreen and advanced safety protocols. While it handles intricate designs flawlessly, occasional delays in software updates could be improved. For small workshops or custom artisans, this engraver offers excellent value with a strong ROI, making it a reliable choice for diverse applications.

Maria Kuznetsov (verified owner) –

The laser engraver excels in performance on wood, acrylic, and leather, delivering precise engravings with minimal setup. Its 40W laser and 2.5k DPI ensure sharp details, ideal for personalized projects like wooden signs or custom leather goods. While the software interface is intuitive, occasional delays occur during complex designs. The price-performance ratio is strong, offering good ROI for small businesses or artists. However, adding an auto-focus feature would enhance usability for thicker materials.

Eduardo Lopez (verified owner) –

The laser engraver excels in performance across materials like wood and acrylic, delivering precise cuts at high speed. The software interface is user-friendly, simplifying project setup, though a steeper learning curve exists for advanced features. Its compact workspace suits small-scale projects but limits larger designs. Ideal for crafting custom jewelry or decorative items, it offers exceptional value with competitive pricing, making it a great choice for hobbyists and small businesses alike.

Teresa Choi (verified owner) –

The laser engraver excels in versatility across materials like wood, acrylic, and leather, delivering crisp details on intricate designs. Its precision is remarkable, with clean cuts on 1/4″ acrylic at high speeds, ideal for signage projects. Setup was straightforward, and the intuitive software simplifies custom patterns. The dual-axis control enhances creativity, though a sturdier gantry would improve stability for heavier materials. At $699, it offers excellent value for hobbyists and small businesses, balancing performance and affordability effectively.

Seung Petrov (verified owner) –

**Laser Engraver Experience**

As a DIY enthusiast, my experience with the laser engraver has been transformative across various projects and aspects of its performance. Here’s a concise breakdown:

### **1. Specific Project Experience**

– **Projects:** I’ve primarily used the laser engraver for custom signs and small furniture engravings.

– **Materials Used:** Wood is my go-to material due to its smooth finish, while acrylic requires careful attention to avoid burn marks. Metal use has been limited but effective with adjusted settings.

– **Challenges Faced:** Ensuring consistent depth on curved surfaces was challenging, as was handling different material thicknesses without compromising quality.

### **2. Technical Performance**

– **Power and Precision:** The engraver excels at 100W for wood and acrylic, providing clean engravings. However, higher power settings are necessary for metals.

– **Software Experience:** Initially had a learning curve with complex vector files, but the drag-and-drop interface became manageable over time.

– **Special Features:** Pause and resume functions are invaluable for large projects, allowing me to manage them more efficiently.

### **3. Business/Creative Impact**

– **Workflow Improvement:** Transitioning from manual carving tools has saved significant time and improved consistency.

– **Client Feedback:** Clients appreciate the precision and finish, leading to increased work opportunities.

– **Return on Investment (ROI):** Achieved ROI within a year due to enhanced efficiency and capability to handle larger projects.

### **4. Comparison & Value**

– **Previous Tools:** Manual carving was slow and inconsistent; this engraver offers faster results with higher precision.

– **Cost-Effectiveness:** Despite initial setup time, the long-term savings and efficiency make it a worthwhile investment.

– **Time Savings:** Projects that once took days now require mere hours, significantly boosting productivity.

Overall, the laser engraver has been an invaluable tool, enhancing both my creative projects and business operations through precision, versatility, and efficiency.

Ricardo Bruno (verified owner) –

“The Laserhawk LH5 has been a lifesaver for my detailed engravings. It cut through my latest metal piece effortlessly, leaving such clean lines—I was amazed!”

David Anderson –

五星好评: This laser engraver delivers exceptional detail and precision. The operation is seamless, software intuitive. Fast engraving speed boosts productivity. Well-built and reliable!