Title: Setting Up the K10 Laser Engraver Effectively

Introduction

Laser engraving is a cutting-edge technology with a multitude of applications across various industries. Whether you’re looking to personalize gifts, create intricate designs, or manufacture parts with precision, a laser engraver can be an invaluable tool. In this guide, we’ll delve into the details of how to set up the K10 laser engraver, ensuring you maximize its potential and get started with your projects smoothly.

Understanding the K10 Laser Engraver

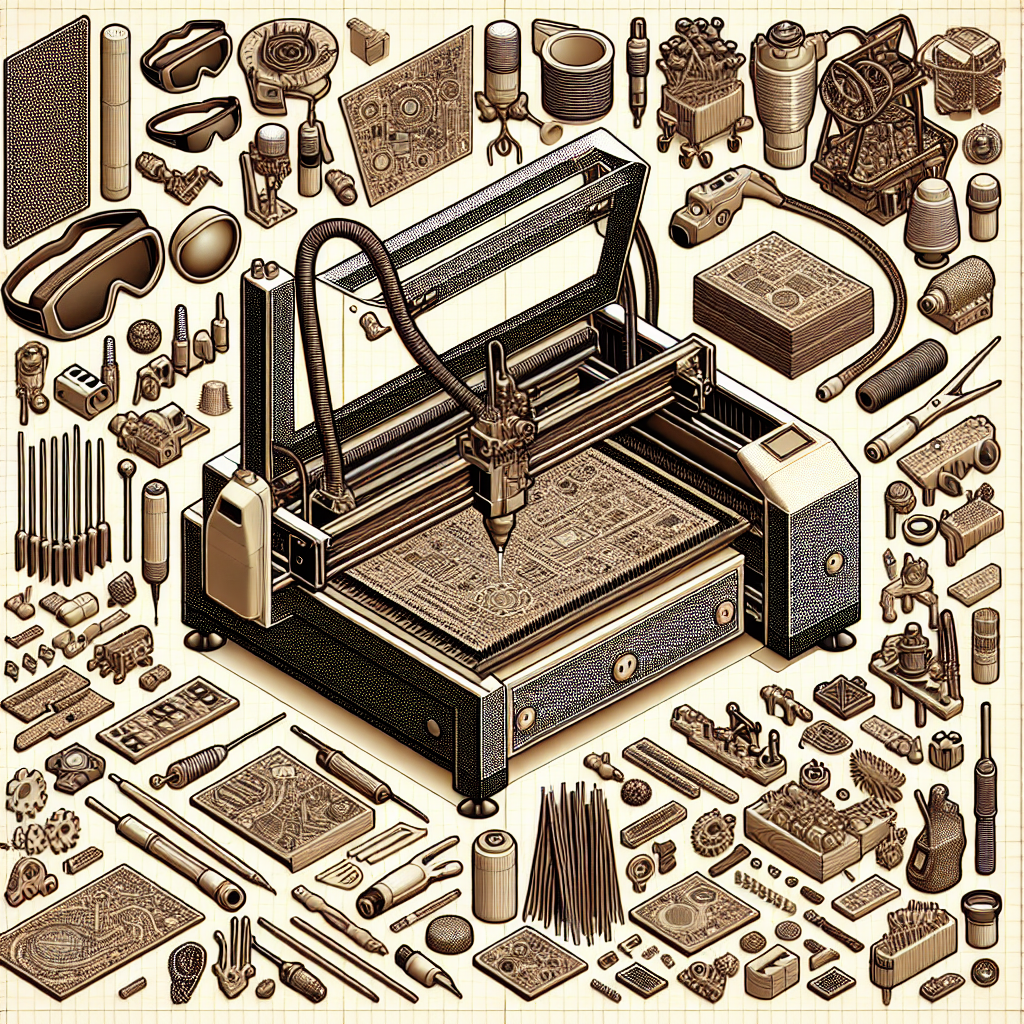

The K10 laser engraver stands out in the market for its versatility and ease of use. It’s designed to handle a wide range of materials and is equipped with user-friendly features, making it ideal for both beginners and experienced users. Let’s explore the machine specifications and features.

This model is compact yet powerful, offering both portability and precision. It features cutting-edge laser technology capable of engraving on materials like wood, plastic, leather, and even certain types of metal. The K10’s software is intuitive, allowing users to easily transform their designs into reality without a steep learning curve.

Material Compatibility

One of the main considerations when setting up a laser engraver is understanding what materials you can work with. The K10 laser engraver is compatible with a variety of materials, making it a versatile choice for different projects.

- Wood

- Leather

- Cardboard

- Plastic

- Fabrics

- Thin metals

When working with these materials, it’s crucial to ensure that they are free of chemicals or coatings that could react adversely during the engraving process. Always conduct a small test engraving first to gauge how the material will respond.

Safety Considerations

Working with laser engraving machines requires strict safety precautions. The intense light and heat generated can cause harm if handled improperly. Here are some key safety considerations when using the K10 laser engraver:

- Always wear protective eyewear while operating the machine.

- Ensure the setup area is well-ventilated to avoid inhaling fumes or particulates.

- Keep flammable materials away from the engraving area.

- Regularly inspect and maintain the machine to prevent malfunctions.

Failure to follow safety guidelines can lead to serious injury or damage to the machine, so taking these precautions is essential.

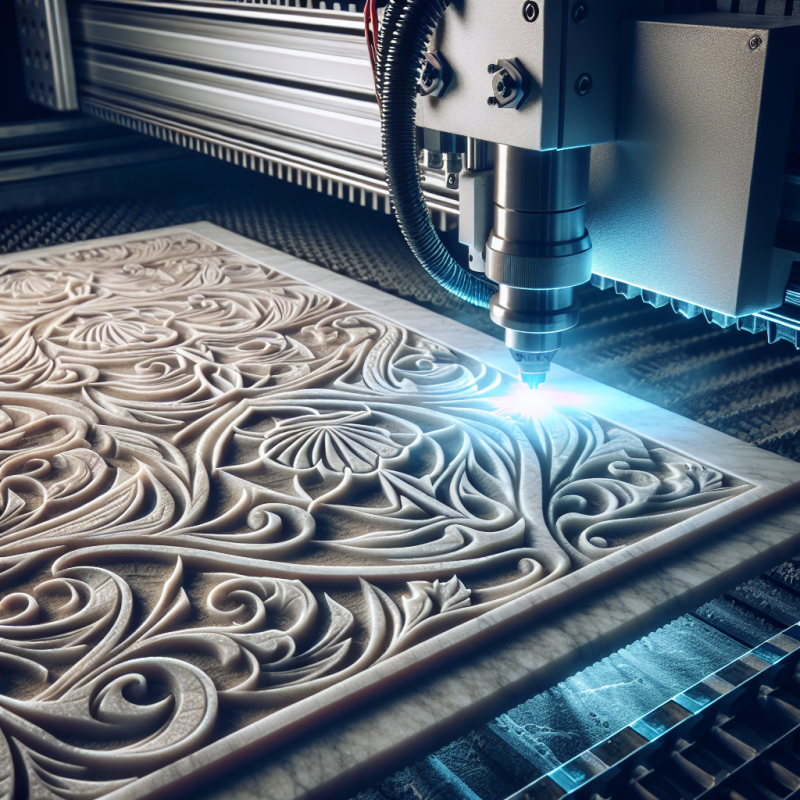

How to Set Up the K10 Laser Engraver

Setting up the K10 laser engraver requires attention to detail to ensure everything is configured correctly for optimal performance. Here’s how to set up the K10 laser engraver from unboxing to first use:

- Unboxing and inspecting: Carefully remove the K10 from its packaging and inspect for any signs of damage during shipping.

- Assembly: Follow the manufacturer’s instructions to assemble any components that were packaged separately.

- Software installation: Install the engraving software on your computer and connect the machine via USB or Bluetooth.

- Calibrating the machine: Follow the calibration procedure outlined in the manual to ensure accuracy in engravings.

- Pre-use checks: Conduct a test run with a non-valuable material to ensure all settings are correct.

For step-by-step instructions, always refer to the detailed manual provided by the manufacturer.

Industry Best Practices

Once you’ve set up your K10 laser engraver, adhering to industry best practices will ensure you get the most out of your machine. Here are some tips:

- Maintain a clean workspace to keep the machine free of dust and debris.

- Regularly update the software to access new features and compatibility options.

- Document your settings for different materials for consistency in future projects.

Cost-Benefit Analysis

Investing in a K10 laser engraver is a commitment. Undertaking a cost-benefit analysis can help you appreciate the value this tool brings. Although the initial cost might seem high, the K10’s versatility enables you to explore a range of profitable projects. Consider the savings when you’re able to handle diverse engraving tasks in-house rather than outsourcing.

Maintenance Tips

To keep your K10 laser engraver in prime condition, regular maintenance is crucial. Here’s how to maintain your machine:

- Regular cleaning: Keep the laser lens and mirrors clean for consistent performance.

- Lubrication: Check the moving parts and apply lubrication as recommended by the manufacturer.

- Software management: Backup your settings and projects regularly to prevent data loss.

Project Ideas and Tutorials

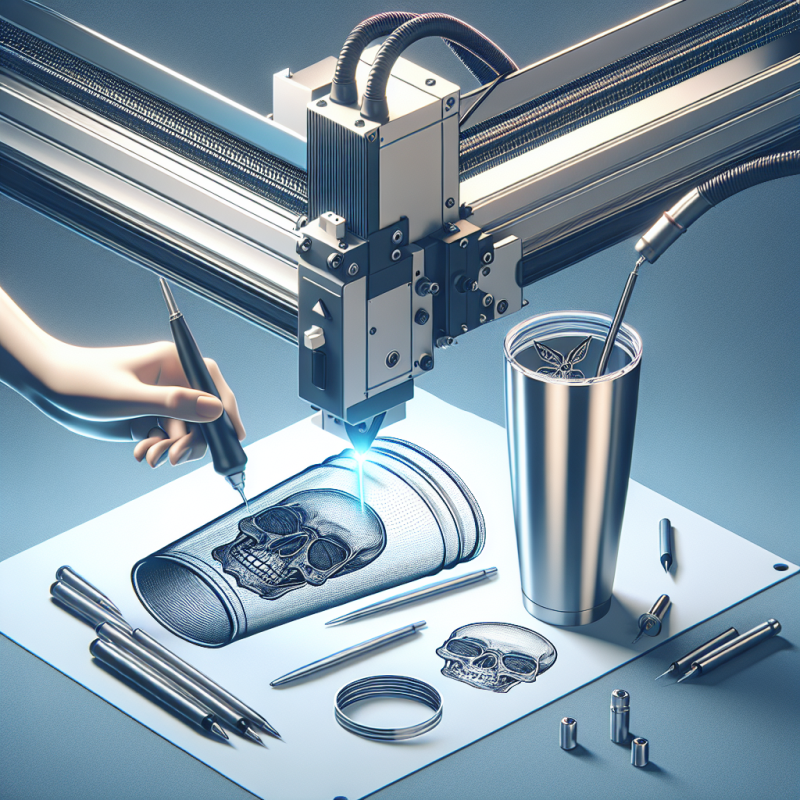

Once your K10 laser engraver is set up, the possibilities are nearly limitless. Here are some project ideas to inspire you:

- Custom jewelry: Create personalized pieces with intricate detail.

- Engraved gifts: Personalize mugs, photo frames, or keychains for every occasion.

- Business branding: Design and engrave logos on promotional materials.

If you’re new to laser engraving, numerous online tutorials can guide you through various types of projects. These resources offer both inspiration and technical guidance to hone your skills.

Conclusion

Mastering how to set up the K10 laser engraver opens up a world of creative possibilities. By following this comprehensive guide, you’ll be well-equipped to capitalize on the K10’s robust features while ensuring safety and efficiency. Embrace the art and functionality of laser engraving as it transforms your design concepts into tangible creations. With ongoing practice, you can further enhance your skills in how to set up the K10 laser engraver and explore various applications that suit your creative needs.