The Future of Craftsmanship: Exploring the World of Laser Engraving Machines

Introduction

In today’s rapidly evolving technological landscape, the crafting and manufacturing industries have seen a significant transformation, largely due to the advent of the laser engraver. This cutting-edge technology has opened up new avenues for creativity and precision, allowing artisans and manufacturers to produce intricate designs and durable markings on a wide range of materials.

Laser Engraving Technology and Applications

At its core, laser engraving technology employs focused light beams to engrave or etch patterns onto various surfaces. This precise and efficient method has numerous applications, ranging from personalized gifts to industrial manufacturing. The laser engraver is integral in industries such as jewelry making, electronics, and even aerospace, offering unparalleled versatility and accuracy.

With the ability to work on complex designs with ease, laser engravers have become essential tools for artists, designers, and engineers alike. They are capable of producing everything from detailed art pieces to functional mechanical parts. The precision offered by these machines outperforms many traditional methods, enhancing both the scope and the quality of creative projects.

Machine Specifications and Features

The capabilities of a laser engraver can vary significantly, based on its specifications and features. The Laserpecker LP5, for example, is known for having a potent 20W fiber diode laser, which is essential for high-speed and high-quality engravings.

- Power output: 20W

- Precision: High-precision fiber optics

- Speed: Rapid engraving speeds

- Software compatibility: Broad range including major design software

- Connectivity: Bluetooth and USB support

These features contribute to the machine’s ability to handle a variety of tasks, from simple cut patterns to complex, layered engravings. The right laser engraver can dramatically improve the workflow and quality of the final product, making it a worthwhile investment for both hobbyists and professionals.

Material Compatibility

A key strength of laser engraving technology lies in its broad material compatibility. The Laserpecker LP5 and similar machines can work with:

- Metals such as stainless steel, aluminum, and precious metals

- Plastics like acrylic and polycarbonate

- Natural materials including wood and leather

- Fabric materials

- Glass and other ceramics

This versatility is invaluable in both commercial settings and creative projects, reducing the need for multiple tools and systems. However, users must consider the specific properties and behaviors of different materials under laser exposure, as factors like thickness and color can influence the engraving results.

Safety Considerations

While the laser engraver boasts a wide array of benefits, it is crucial to observe safety precautions to prevent accidents. Always wear protective eyewear specifically designed for laser work, as the light emitted can cause significant damage to your eyesight.

Ensure that the workspace is well-ventilated to cope with any fumes released during engraving, and be aware of the potential fire hazards when working with flammable materials. Regular maintenance and adherence to the manufacturer’s guidelines are essential to keep the machine functioning safely and effectively.

Industry Best Practices

To fully leverage the capabilities of a laser engraver, it’s important to follow industry best practices. These include:

- Undertaking proper training and gaining familiarity with the machine before embarking on complex projects.

- Regular maintenance routines, such as cleaning lenses and checking for any software updates that improve functionality.

- Keeping up-to-date with the latest advancements in laser technology to stay competitive in the market.

- Ensuring the machine is placed in a stable environment to ensure high precision and minimize errors.

These practices help to optimize the performance and lifespan of your equipment while ensuring the safety of operators and the quality of output.

Cost-Benefit Analysis

Investing in a laser engraver can initially appear daunting due to the costs involved. However, a comprehensive cost-benefit analysis often reveals its value. Compared to traditional engraving methods, laser technology offers the following benefits:

- Reduced labor costs due to automation and precision

- Low material wastage, contributing to overall cost efficiency

- Increased production speeds, resulting in faster turnaround times

- Enhanced product quality leading to higher customer satisfaction

These factors culminate in quicker return on investment, as the reduction in production costs and increase in product output generally outweigh the initial purchase and ongoing maintenance expenses.

Maintenance Tips

To maintain optimal performance and prolong the life of your laser engraver, regular maintenance is key. Here are some essential tips:

- Keep the work area and machine free of dust and debris to prevent operational issues.

- Regularly inspect machine components, especially the laser and lenses, for wear and tear.

- Lubricate moving parts as outlined in your machine’s manual to ensure smooth operation.

By following these strategies, you can effectively minimize downtime and reduce the likelihood of costly repairs.

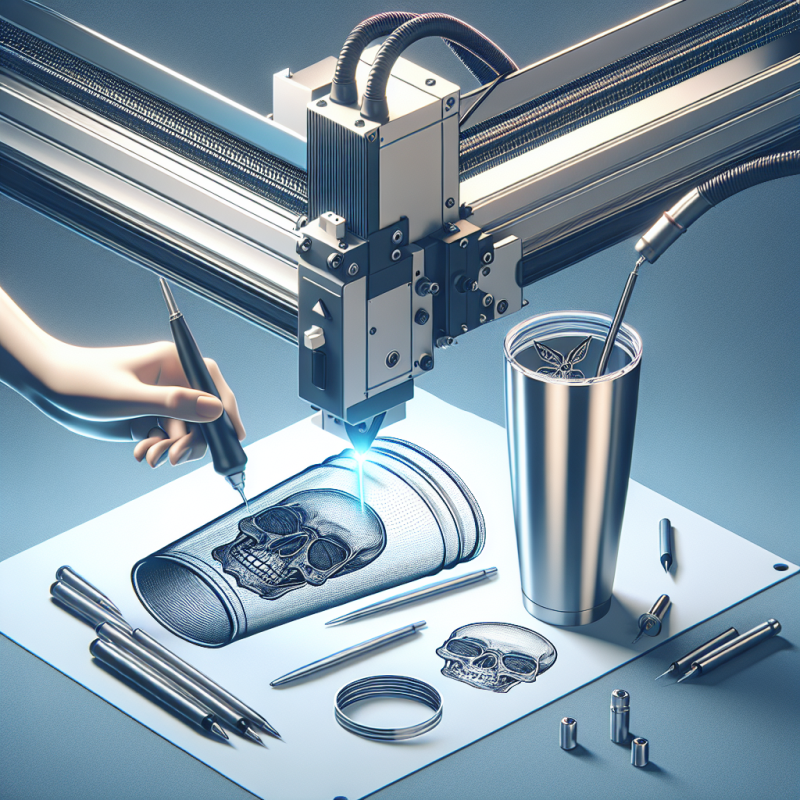

Project Ideas and Tutorials

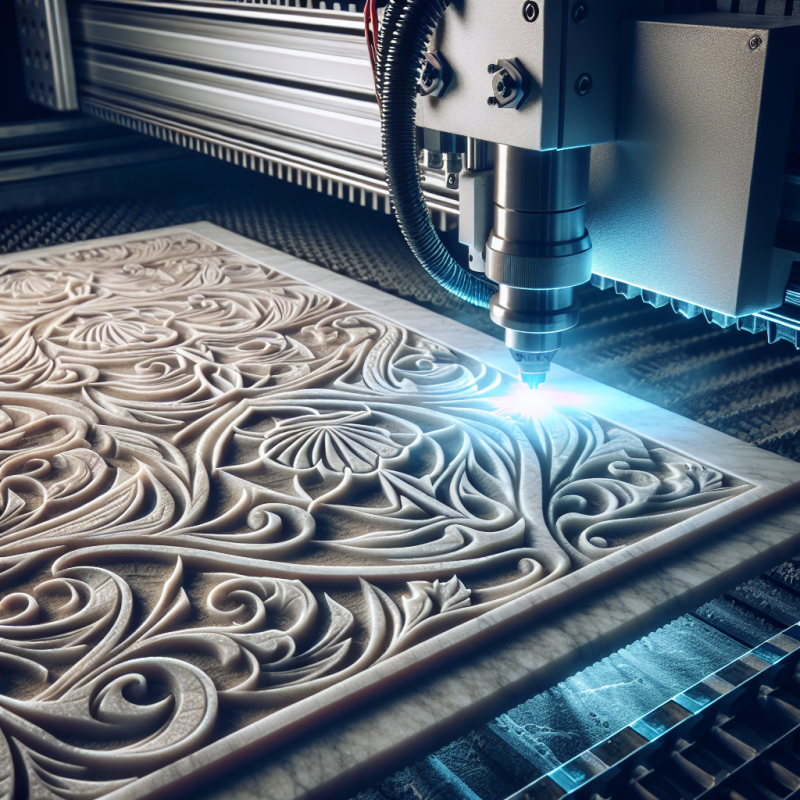

The possibilities with a laser engraver are vast and exciting. Here are some project ideas to spark creativity:

- Custom-designed jewelry pieces, reflecting unique patterns or personal messages

- Engraved woodwork, such as intricate patterns on furniture or decor items

- Personalized assets for businesses, including engraved logos on products

- Educational models with precise engravings for illustrations and experiments

Additionally, online tutorials provide valuable guidance and inspiration, whether you are a beginner or an advanced user. Armed with the proper knowledge and creativity, the applications of the laser engraver are limited only by your imagination.

Conclusion

The advent of the laser engraver has undoubtedly revolutionized multiple industries, transforming how we approach design and manufacturing. With expansive applications, responsive technology, and efficient productivity, these machines are integral to supporting the demands of modern craftsmanship and production.

As we continue to explore the potential of laser engraving technology, it remains clear that investing in such equipment not only enhances the creative process but also contributes to innovative and sustainable production methods in the future.