The Power and Precision of Aluminum Laser Engravers

Introduction

In the realm of modern manufacturing and crafting, technology has continued to evolve at an unprecedented rate, offering innovative tools that redefine how we approach material manipulation. One such transformative tool is the aluminum laser engraver. Known for its versatility and precision, it has become an indispensable asset in various industries. From personal projects to industrial applications, this equipment proves its worth time and again.

Laser Engraving Technology and Applications

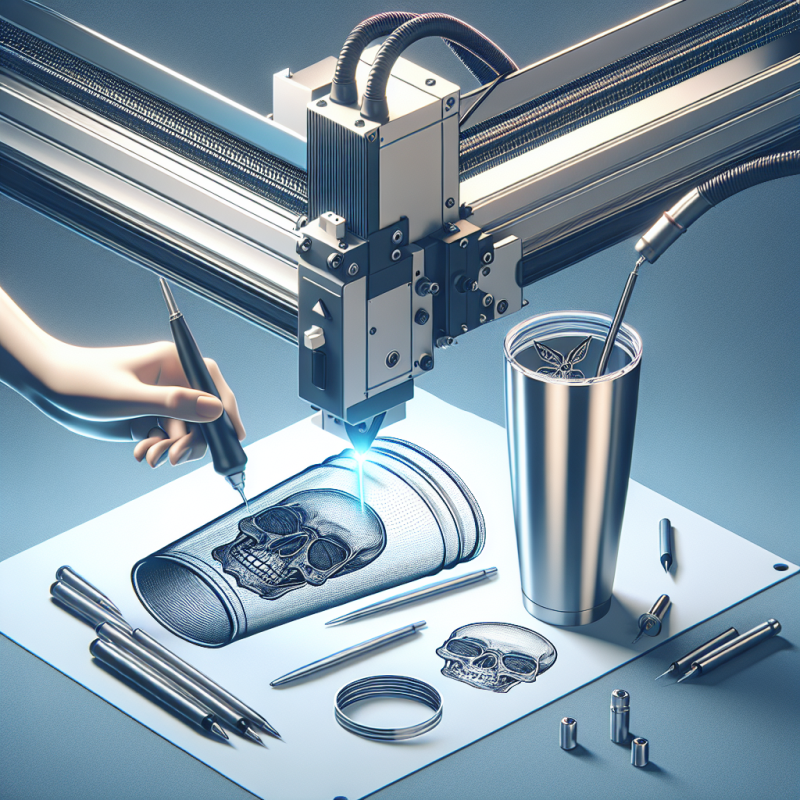

Laser engraving technology is a marvel of precision, using highly concentrated laser beams to etch patterns, logos, and text onto various materials, including metals like aluminum. This capability has broadened the scope of what can be achieved, enabling artists, hobbyists, and professionals to create intricate designs with ease. One of the significant advantages of an aluminum laser engraver is its ability to deliver consistent results with impeccable accuracy.

Laser engravers are extensively used in industries such as aerospace, automotive, and electronics. They are crucial in product labeling, customization of components, and prototyping. The technology also finds applications in signage creation, jewelry design, and artwork reproduction. The use of a laser engraver ensures that each etching is as precise and detailed as the previous one, facilitating mass production without compromising on quality.

Machine Specifications and Features

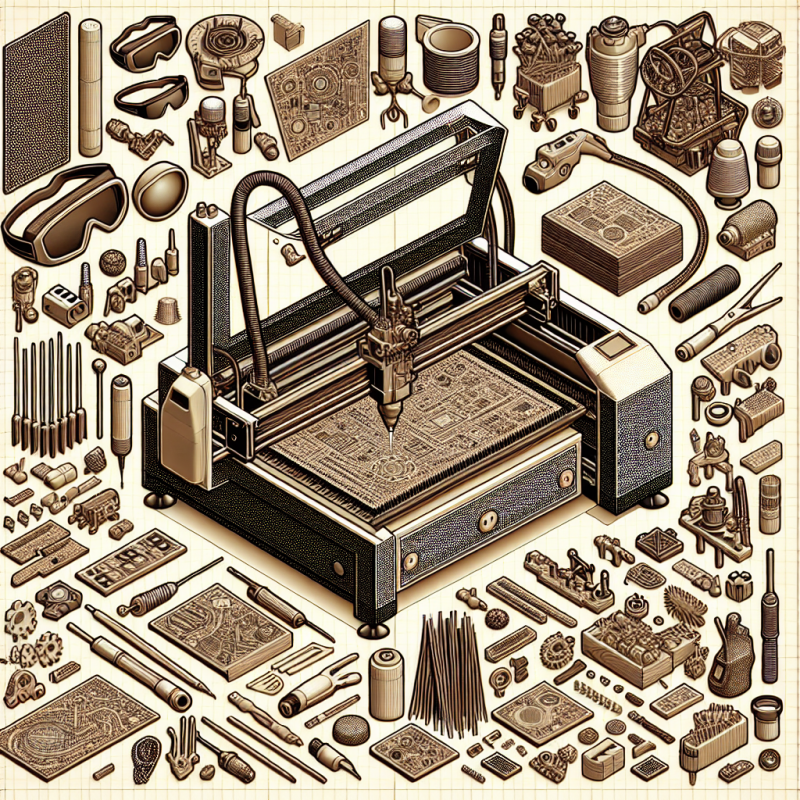

Choosing the right aluminum laser engraver involves understanding its specifications and features. Typically, these machines boast high-resolution engravings and different power settings to accommodate various materials. Key features include user-friendly software, adjustable laser intensity, and a robust frame to support stable operations. The inclusion of safety interlocks and emergency stop functions is also common to ensure user safety.

An advanced laser engraver may include a touchscreen interface and remote operation capabilities, allowing for greater flexibility and ease of use. The precision of the engraver is often highlighted by its ability to adjust laser focus automatically, optimizing the results based on the material type and thickness.

Material Compatibility

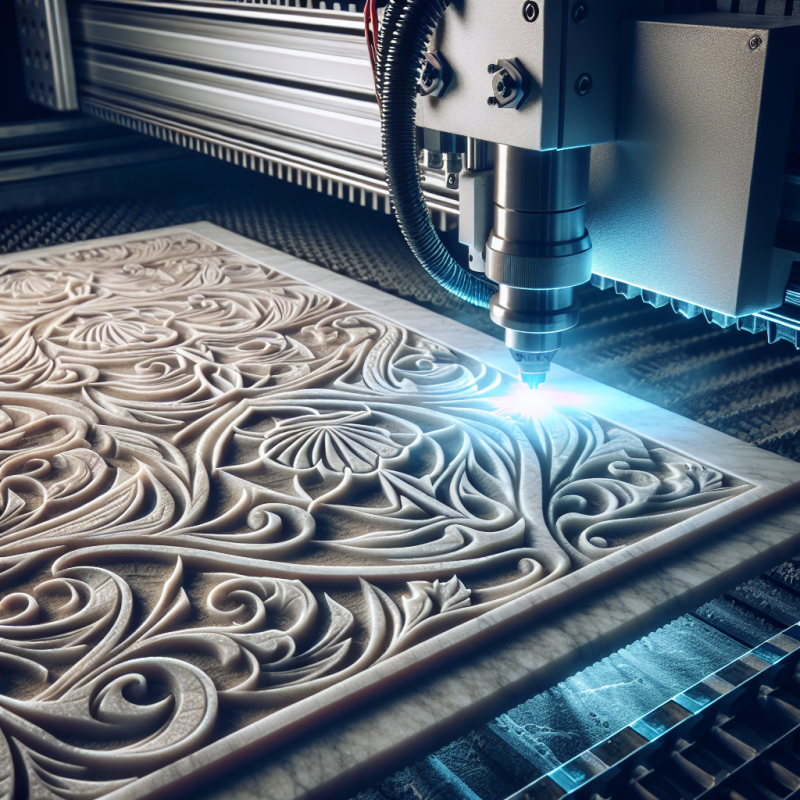

The versatility of a laser engraver is largely determined by its ability to work with different materials. The aluminum laser engraver excels in this area, not only capable of etching on aluminum but also effective with various other substrates. These include plastics, wood, leather, glass, and certain types of stone.

When working with metals, particularly aluminum, users must adjust the laser engraver’s settings to achieve the desired depth and style of the etch. They must also ensure that the machine is compatible with the specific type of aluminum used, as alloys can influence the engraving process.This adaptability makes the laser engraver a valuable tool across multiple disciplines and projects.

Safety Considerations

Operating an aluminum laser engraver safely requires adherence to several key practices. First and foremost, it’s critical to wear protective eyewear to guard against the intense light emitted by the laser. The work area should be well-ventilated to disperse any fumes generated during the engraving process.

It’s also important to be aware of the laser engraver’s power, ensuring that its settings are appropriate for the material in use. Misuse or inappropriate settings can lead to undesired results or damage the material. Always follow the manufacturer’s instructions and guidelines to maintain a safe working environment.

Industry Best Practices

To maximize the efficiency and lifespan of an aluminum laser engraver, there are several best practices to follow. Routine maintenance checks and cleaning help keep the machine operating optimally. It’s beneficial to regularly inspect and clean the lens and mirrors as debris can affect the quality of the engraving.

Calibrating the machine regularly ensures that the engravings are accurate and consistent. It’s also advisable to keep a log of maintenance activities and any issues encountered. This practice not only helps in troubleshooting but also extends the life of the equipment.

Cost-Benefit Analysis

Purchasing an aluminum laser engraver represents a significant investment, but the benefits it brings often outweigh the initial costs. The machine’s ability to perform precise engravings without the need for consumables like inks or blades leads to long-term savings. Additionally, the potential for reducing turnaround times and increasing productivity can significantly boost revenue.

For businesses, the customization capabilities open new revenue streams, enabling them to offer personalized products to customers. For hobbyists, the creative possibilities are endless, allowing them to create unique and detailed pieces with relative ease.

Maintenance Tips

Regular maintenance of an aluminum laser engraver is paramount in ensuring its longevity and performance. Adequately lubricating moving parts and ensuring the laser tube is in good condition can prevent operational hiccups.

Software updates should not be overlooked, as they often include bug fixes and performance improvements. Keeping the workspace clean and free from excess dust and debris reduces the need for frequent internal cleanings and helps extend the machine’s lifespan.

Project Ideas and Tutorials

The creative applications for an aluminum laser engraver are boundless. From decorative plaques and model building to intricate jewelry designs and custom kitchenware, the possibilities can spark inspiration in both novice users and experienced artisans.

Tutorials abound online, providing project ideas that range from simple engravings to complex designs. Engraving personalized gifts for friends and family or crafting bespoke home decor are popular endeavors. These projects not only serve as a creative outlet but also offer a functional application of the engraver’s capabilities.

Conclusion

The aluminum laser engraver represents a significant advancement in both manufacturing and artistic fields. Its ability to produce precise etchings on a variety of materials allows users to explore a wide range of creative and commercial possibilities. Understanding its workings, adhering to safety protocols, and practicing regular maintenance ensures that this powerful tool remains a valuable asset in any workshop.

As you consider whether a laser engraver is the right choice for your needs, ponder these questions: What types of projects do you envision undertaking? How might an engraver improve your current workflow or creations? With careful consideration and the right investment, an aluminum laser engraver can transform the way you engage with your craft or business.