The Ultimate Guide to Laser Engravers and Cutters

Introduction

In recent years, the use of laser engraver and cutter technology has skyrocketed across various industries. These machines are revolutionizing manufacturing, crafting, and even home DIY projects with their precision and ability to work with a broad range of materials. But what exactly makes a laser engraver and cutter an essential tool? This comprehensive guide is designed to answer your pressing questions about laser engraving machines and equip you with the knowledge to make informed decisions about investing in them.

Understanding Laser Engraving Technology

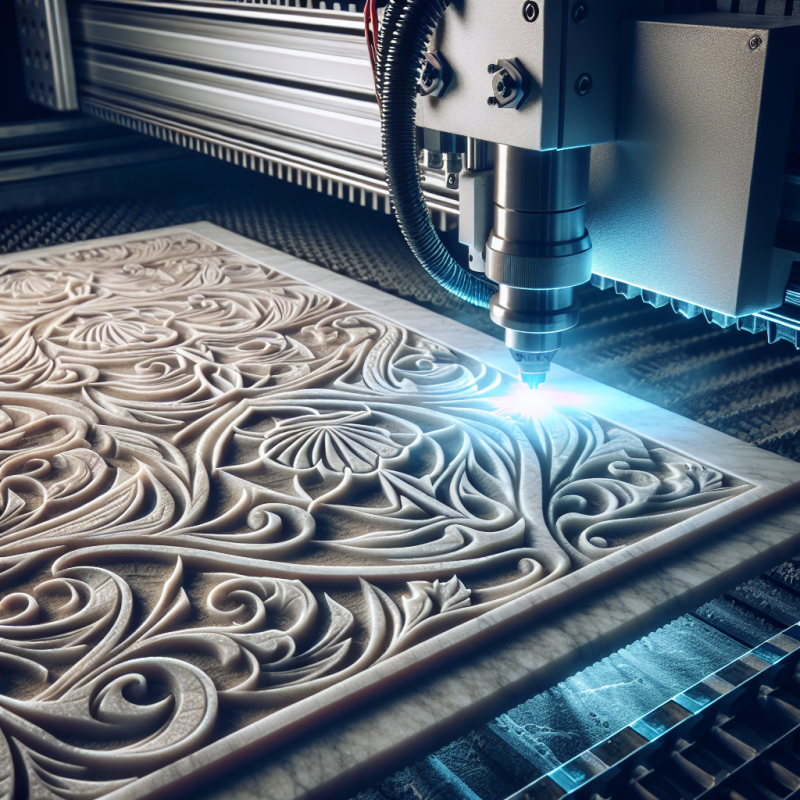

The core of a laser engraver and cutter is its ability to focus a beam of light to etch, mark, or cut material. These machines offer a non-contact process, meaning there is no mechanical force applied to the workpiece, resulting in a precise cut or engraving. This technology is ideal for applications where delicate or high-detail work is required.

Laser engraving technology primarily works by using a laser beam to vaporize materials into fumes, carving an impression. Unlike traditional engraving, it offers higher speed and precision, making it ideal for intricate designs and small-scale applications.

Applications of Laser Engraving Machines

Laser engraving machines are versatile and can be used in numerous industries, including:

- Manufacturing: Ideal for marking parts with serial numbers, logos, or intricate designs.

- Jewelry Making: Engraving detailed patterns on metals and stones.

- Advertising: Creating signs, displays, and promotional items.

- Personalization: Customizing gifts, awards, and personal items.

- Art and Craft: Cutting stencils, creating art pieces, and more.

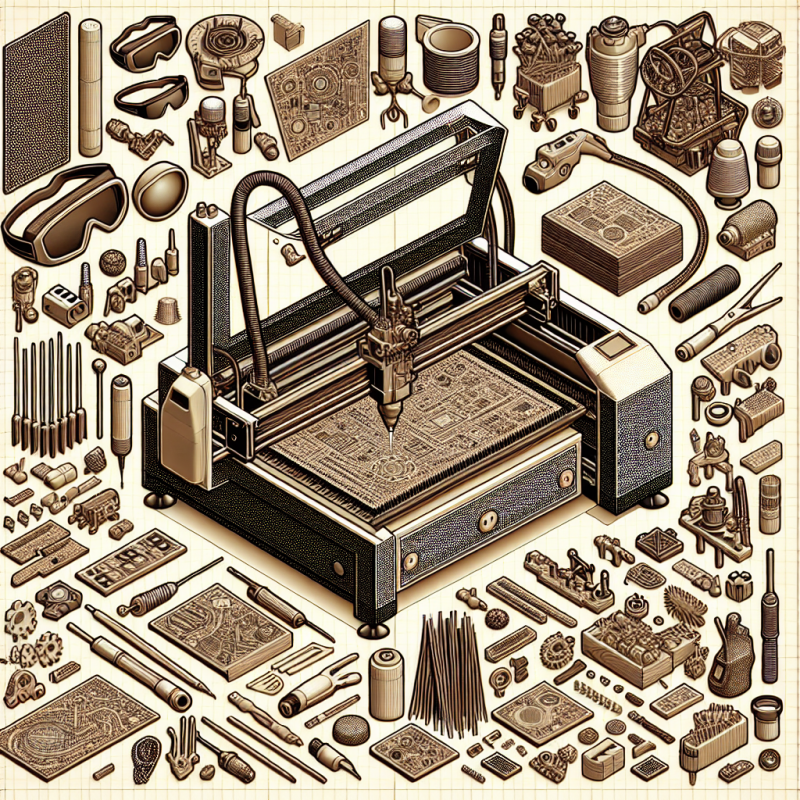

Machine Specifications and Features

When selecting a laser engraver and cutter, understanding the specifications and features can make a significant difference:

- Laser Power: Determines the thickness and types of materials you can cut or engrave.

- Working Area: The size of the material that the machine can accommodate.

- Resolution: Higher resolution provides finer detail in engravings.

- Software Compatibility: Many machines come with proprietary software, while others are compatible with third-party software.

Material Compatibility

Laser engravers and cutters are compatible with a wide range of materials:

- Wood: Excellent for engraving and cutting.

- Acrylic: Often used for signage and awards.

- Metal: Suitable for marking and engraving with specific laser types.

- Glass: Ideal for engraving but not cutting.

- Fabric: Allows for custom designs but requires careful consideration of material flammability.

Safety Considerations

Operating a laser engraver and cutter safely is paramount:

- Protective Eyewear: Always wear appropriate laser safety glasses.

- Ventilation: Ensure adequate ventilation to avoid inhaling fumes.

- Material Safety: Research the material to ensure it can be safely engraved or cut.

- Fire Hazards: Keep a fire extinguisher nearby and never leave the machine unattended while operating.

Industry Best Practices

Here are some industry best practices for using laser engraver and cutter technology:

- Regularly maintain and service the machine to ensure optimal performance.

- Keep the machine’s lens and mirrors clean to avoid quality degradation.

- Invest time in learning the machine’s software to maximize its capabilities.

- Experiment with different materials and settings to expand creative applications.

Cost-Benefit Analysis

Investing in a laser engraver and cutter can be a significant expenditure. However, the cost is often justified by the benefits:

Benefits: The precision, speed, and ability to customize numerous types of materials often result in increased productivity and the potential for new revenue streams. Additionally, the versatility of these machines often reduces the need for multiple different tools, saving costs in the long run.

Costs: These can include the initial investment, ongoing maintenance, and the cost of materials and replacement parts. However, the return on investment is typically very favorable when factoring in increased capability and reduced waste.

Maintenance Tips

Regular maintenance is crucial for the longevity and performance of your laser engraver and cutter:

- Regularly clean and replace the filters and fans to prevent overheating.

- Inspect the laser tube for signs of wear or laser power reduction.

- Lubricate moving parts to keep the structure robust and responsive.

- Calibrate the laser alignment periodically to ensure cutting precision.

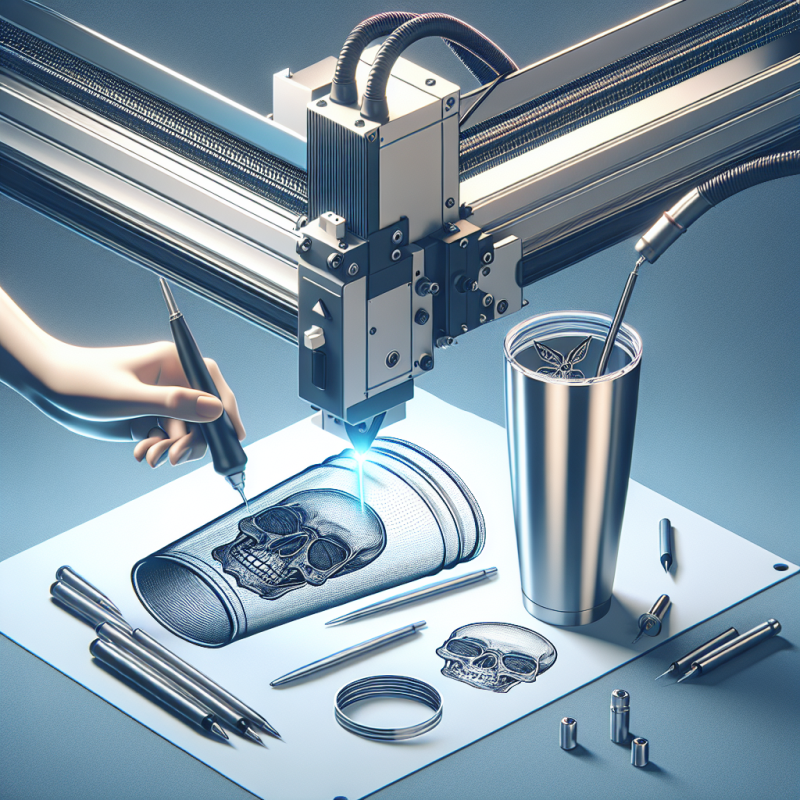

Project Ideas and Tutorials

Ready to unleash your creativity with your laser engraver and cutter? Here are a few project ideas to get you started:

- Design personalized wooden puzzles for children.

- Create intricate cut-out greeting cards for special occasions.

- Engrave custom designs on leather wallets or bags.

- Cut acrylic to build custom display stands or models.

For newcomers, online tutorials and video guides can provide a wealth of information, helping you to fully realize the potential of your laser engraving machine.

Conclusion

The laser engraver and cutter is more than just a tool; it is a gateway to innovation and creativity. Whether you’re in manufacturing, design, or the arts, these machines can significantly enhance your capability to create, personalize, and improve efficiency. As technology continues to evolve, investing in a laser engraver and cutter could very well be the decision that propels your business or hobby to new heights.

Still have questions about laser engraving machines? Feel free to dive deeper into specific aspects or reach out to industry experts for tailored advice. The possibilities are as vast as your imagination when it comes to this transformative technology.